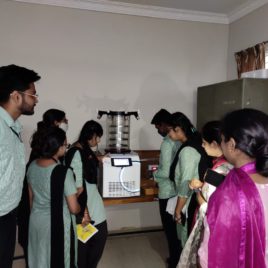

Students get hands-on experience in various food processing/preservation methods such as hot air drying, freeze-drying, extraction of essential oils, pickling, jam, jelly, sauce and candy preparation, wine preparation etc. Students develop and assemble food processing equipment based on modern technologies such as Microwave Assisted Extraction, IR dryer etc. They are involved in developing innovative food products viz. cup-cake from ragi and starch free potato residue and vitamin and fibre enriched curd. They learn to use equipment for determining the food composition. University is equipped with various analytical equipment including HPLC which students use for food product characterization. Students have made edible film from potato starch and are working to utilize other agro wastes for biodegradable packaging to address environmental issues. Students undergo internship in small scale bakery unit, mini dairy unit and SC-CO 2 extraction unit where they gain skills and confidence of working in large production plants.

Domain Track: Food Processing

Course Attendees

Still no participant

Course Reviews

Still no reviews

Track Total Credits (T-P-P) (3-15-11) Total 29

Course Divisions

- Processing Technology of Cereals and Millets CUFP2310(1-2-0)

- Processing Technology of Legumes and Oilseeds CUFP2311(1-2-0)

- Processing Technology of Fruits, Vegetables, Spices and Condiments CUFP2312(1-2-0)

- Product Development and Packaging Technologies CUFP2313(0-3-0)

- Food Standards and Regulations and HACCP Systems CUFP2314(0-3-0)

- Sensory Evaluation and Nutritional Labelling of Foods CUFP2315(0-3-0)

- AELP Linked Project CUFP2316(0-0-11)

Domain Track Objectives:

- Impart an understanding of general process flow of various food products, physical principles of operation for various types of equipment and the impact of the processing on the physical, chemical and sensory properties of the food products

- Understand the concepts and principles of processing and packaging techniques and the effects of processing parameters on product safety and quality

- Gain insights into the scientific, regulatory, and consumer interests that interact in determining the safety of food

Domain Track Learning Outcomes:

Upon completion students will be able to:

- Operate and maintain processing equipment

- Formulate and make processed food products

- Adopt hygienic and sanitation practices during product preparation

- Understand and develop HACCP plans based on the standards and regulations

- Perform sensory evaluation and develop nutrition labels for food products

Career Scope:

- Students developing aptitude for work and right skills will find ample job opportunities in public and private sector, food research laboratories, catering companies, food wholesalers, restaurants etc.

- It will lay base for students to pursue certification courses in nutrition, IPR, food preservation etc.

- Students could become entrepreneurs in starting food business.

Domain Syllabus:

1. Processing Technology of Cereals and Millets (1-2-0)

Theory

General Introduction, Properties of cereals and millets, Paddy Processing, Parboiling of paddy, Drying, Wheat processing, Corn milling, Malting of cereals, Rice fortification methods, Food packaging and quality

Practice

Physical properties of cereals, Physical and frictional properties of cereals, Moisture content of grain, Parboiling and cooking quality of paddy, Preparation of puffed and flaked rice and sorghum. Estimation of milling qualities in a rice mill, Proximate analysis of cereal based products, Estimation of moisture content and drying time calculations

2. Processing Technology of Legumes and Oilseeds (1-2-0)

Theory

General Introduction, Morphology, Pulse Milling, Pulse Processing, Oil seed Milling and problems in oil seed milling, Refining of oils

Practice

Esimation of physical properties of legumes and oilseeds, Determination of proximate composition of selected pulses and oilseeds, Preconditioning of pulses before milling, Laboratory milling of selected pulses and oilseeds and its quality evaluation, Laboratory refining of selected oils, Study of cooking quality of pulses

3.Processing Technology of Fruits, Vegetables, Spices and Condiments (1-2-0)

Theory

General Introduction, Primary processing and packaging, Canning, FSSAI specifications and food quality, Value added products, Spices and Condiments, Spice Board of India

Practice

Primary processing of selected fruits and vegetables, Estimation of TSS, pH, Acidity, and Ascorbic acid, Study of steps of Can making process, Processing of food using salt, high concentration of sugar, acidulants, and fermentation techniques, Drying of fruits and vegetables using freeze-drying, Adulteration test of spices

4. Product Develoment and Packaging Technologies (0-3-0)

Product design process, Product development process, Formulation and composition description, Process flow diagram, Process development, Packaging principles, Types of packaging - MAP, CAP, VP, Preparation and packaging of food products

5. Food Standards and Regulations and HACCP Systems (0-3-0)

Codex Alimentarius, FSSAI, ISO, SQF, GMP's, SOP's, SSOP's, FHP, HACCP Principles, APEDA, Spice Board

6. Sensory Evaluation and Nutritional Labelling of Products (0-3-0)

Sensory attributes of foods, Sensory evaluation methodology, Threshold measurements, Difference Tests, Descriptive analytical methods, Consumer tests, Nutritional labelling

7. AELP Linked Project (0-0-11)

- 1. Formulate and Preparation of Products

- 2. Develop HACCP plans for formulated products

- 3. Identify standards and regulations for the food products

- 4. Sensory evaluation of the developed products

- 5. Label and develop appropriate packaging and storage methods

Suggested References

- Post Harvest Technology of Cereals, Pulses and Oilseeds. A.Chakravarty

- Industrial Processing of Fruits and Vegetables. U.D. Chavan and J.V. Patil. 2013. AstralInternational Pvt. Ltd., New Delhi.

- Advances in Preservation and Processing Technologies of Fruits and Vegetables. S. Rajarathnam and R.S. Ramteke. 2011. New India Publishing Agency, New Delhi.

- Fruit & Vegetable Preservation: Principles and Practices. R.P. Srivastava and Sanjeev Kumar. 2002., 3rd Ed. International Book Distribution Co., Delhi.

- Preservation of Fruits and Vegetables. Girdhari Lal, G.S. Siddappa and G.L. Tandon. 1959. ICAR, New Delhi.

- Spices and Condiments. Pruthi, J.S., 1980. Academic Press, New York.

- Methods for Developing New Food Products – An Instructional Guide. Fadi Aramouni, Kathryn Deschenes, 2015

- Food Packaging – Principles and Practice. Gordon L. Robertson. CRC Press, Taylor and Francis Group

- Sensory Evaluation of Food – Principles and Practice, Harry T. Lawless and Hildegrade Heymann

Session Plan:

1. Processing Technology of Cereals and Millets

Session 1.1

Theory

Present Status and Future Prospects of Cereals and Millets, Morphology, Chemical Composition, and Nutritive Value

Practice

Problem Session on Physical Properties of Cereals

Session1. 2

Theory

Physico-chemical Properties of Cereals

Practice

To Determine Physical and Frictional Properties of Cereals

Session 1.3

Theory

Paddy Processing and Rice Milling

Practice

Determination of Moisture Content of Grain

- PDF -Paddy Processing...

- Video -Rice Processing...

- Video -Mini Rice Mill...

- Video -Moisture Content - Wet and Dry Basis...

- Video -Calculating Moisture Content - Wet and Dry Basis...

Session1. 4

Theory

Parboiling of Paddy

Practice

Study of Parboiling of Paddy

- PDF -Paddy Parboiling...

- PDF -Paddy Parboiling Methods...

- Video -Automated Paddy Parboiling Process...

- Video -Paddy Parboiling Process...

Session1. 5

Theory

Wheat Processing

Practice

Milling of Wheat

- PDF -Wheat Processing...

- Video -Wheat Milling...

- Video -Wheat Flour Milling...

Session 1.6

Theory

Corn Milling

Practice

Preparation of Popcorn

- PDF -Corn Milling...

- Video -Corn Flour Milling...

- Video -Industrial Popcorn Machine...

Session1. 7

Theory

Malting of Cereals

Practice

Preparation of Puffed and Flaked Rice

- PDF -Malting of Cereals...

- Video -Cereal Malting...

- Video -Rice Flakes Machinery...

Session1. 8

Theory

Rice Fortification Methods

Practice

Estimation of Milling Qualities and Milling Efficiency of a Rice Milling Machine

- PDF -Rice Enrichment and Fortification...

- Video -Rice Fortification...

- Video -Rice processing...

Session1. 9

Theory

Milling of Barley

Practice

Study of Milling of Barley and Oats

- PDF -Milling of Barley...

- Video -Oats Processing...

Session 1.10

Practice

Preparation of Noodles

Milling of Rye and Sorghum

- Video -Automatic Noodle Making Machine...

- Video -Miling of Sorghum...

Session 1.11

Practice

Determination of EMC and Calculating Drying Depth

2. Processing Technology of Legumes and Oilseeds

Session 2.1

Theory

- Present Status and Future Prospects of Legumes and Oilseeds

- Morphology of Legumes and Oilseeds

Practice

- Determination of Physical Properties of Legumes

- PDF -Morphology of Legumes and Oilseeds...

- Session 2.1...

- Video -Moisture and Ash Analysis...

Session 2.2

Theory

- Anti-nutriitonal Compounds in Legumes and Oilseeds

Practice

- Classification and Types of Legumes and Oilseeds

- PDF -Anti nutrients compounds...

- Session 2.2...

- Video -Antinutrients in Plants...

Session 2.3

Theory

- Types of Milling Methods, Machinery, Milling Quality and Efficiency

Practice

- Determination of Proximate Composition of Selected Pulses and Oilseeds

- PDF -Pulse Milling...

- Session 2.3 ...

- Video -Dal Milling...

Session 2.4

Theory

- Factors Affecting Quality and Quantity in Dhal Milling

Practice

Session 2.5

Theory

- Pulse Processing

Practice

- Preconditioning of Pulses before Milling

- PDF -Processing of Pulses ...

- Session 2.5 ...

- Video -Lentil Peeling and Splitting...

- Video -Pulses Cleaning Machine...

Session 2.6

Practice

- Methods of Removal of Anti-nutritional Compounds from Pulses

- Laboratory Milling of Selected Pulses and its Quality Evaluation

- Session 2.6 ...

- Video -Methods for Removing Antinutrional Compounds...

Session 2.7

Theory

- Oil Extaction Methods

Practice

- Mini Oil Mill

- PDF -Oilseed Milling ...

- Session 2.7, 2.8, 2.9, 2.10 ...

- Video -Mini Oil Mill...

Session 2.8

Theory

- Oil Milling Quality and Efficiency

Practice

- Laboratory Milling of Selected Oilseeds

- PDF -Oilseed Extraction ...

- Video -Oil Extraction Machine...

Session 2.9

Practice

- Methods of Removal of Anti-nutritional Compounds from Oilseeds

- Video -Anti Nutritional Compounds in Nuts...

Session 2.10

Theory

- Problems in Oil Milling and Desolvenitization

Practice

- Laboratory Refining of Selected Oilseeds

- PDF -Refining of Oil ...

- Video -Refining of Oils - Degumming Process...

Session 2.11

Theory

- Hydrogenation of Oils

Practice

- Hydrogenation of Oils

- PDF -Hydrogenation of Oil ...

- Session 2.11 ...

- Video -Hydrogenation of Oils...

Session 2.12

Theory

- Solvent Extraction

Practice

- Super Critical Extraction Unit

- PDF -Solvent extraction ...

- PDF -Super Critical Fluid Extraction...

- PDF -Processing of Legumes and Oilseeds Manual ...

- Session 2.12 (1)...

- Session 2.12 (2)...

- Video -Solvent Extraction Plant...

3. Processing Technology of Fruits, Vegetables, Spices, and Condiments

Session 3.1

Theory

- Production and Processing of Fruits and Vegetables, Principles and Preservation Methods

Practice

- Primary Processing of Selected Fruits and Vegetables

- PDF -Study Material Lecture 01- Importance and Scope of Fruit and Vegetable Preservation in India...

- PDF -Practical 1...

- Food Processing Policy Paper...

- Video -Primary Processing of Local Vgetables...

Session 3.2

Theory

- Primary Processing and Packaging

Practice

- Estimation of Total Solids

- PDF -Study Material Lecture 02 - Primary Processing and Packaging...

- PDF -Practical 2 Determination of Total Soluble Solids...

- Video -Fruit and Vegetable Processing

- Video -Food Quality Refractometer...

Session 3.3

Theory

- Canning

Practice

- Estimation of pH and Acidity of Products

- PDF -Study Material Lecture 03 - Canning...

- PDF -Practical 3 Determination of pH...

- Video -General Principles of Canning

- Video -Canned Vegetable Process...

- Video -Determination of pH...

Session 3.4

Theory

- FSSAI Specifications and Food Quality

Practice

- Estimation of Ascorbic Acid and Effect of Heat Treatment

- PDF -Study Material Lecture 04 FSSAI Specification for Jam Jelly Marmalade and Glazed, Crystallised Fruits...

- PDF -Practical 4 Determination of Ascorbic Acid...

- Ascorbic acid content determination (1)...

- Video -Food Testing in India - FSSAI...

- Video -Analysis of Ascorbic Acid...

- Video Vitamin C Titration...

- Video -Jelly Preparation...

- Video -Preparation of Marmalade...

- Video -Food Recall...

- Video -Food Safety...

Session 3.5

Theory

- Value Added Products

Practice

- Steps in Canning

- PDF -Study Material Lecture 05 Value Added Products - Pectin and Vinegar...

- PDF -Practical 5 Canning Steps...

- Video -Canning Process...

Session 3.6

Theory

- Spices and Condiments

Practice

- Preparation and Evaluation of Pectin Products

- PDF -Study Material Lecture 6.1 Technology of Spices and Condiments...

- PDF -Practical 6 Extraction and Characterization of Pectin from Apple Malus Pumila Cv Amri Peel Waste...

- Video -Apple Pectin...

- Video -Apple Cider Vinegar...

Session 3.7

Theory

- Value Added Products from Spices and Condiments

Practice

- Food processing with High Sugar - Preparation of Jam

- PDF -Study Material Lecture 6.2 Present Status of Indian Spice Industries...

- PDF -Practical 7 Preparation of Jam...

- Video -Preparation of Jam...

Session 3.8

Theory

- Spice board of India

Practice

- Processing of Food with Salt - Pickle Preparation

- PDF -Study Material Lecture 6.3 Nomenclature and Classification of Spices and Condiments...

- PDF -Practical 8 - Pickels...

- Video -Pickle Preparation...

Session 3.9

Practice

- Processing of Food with Acidulants

- PDF -Study Material Lecture 6.4 Chemical Composition of Spices and Condiments...

- PDF -Practical 9 Vinegar Pickles...

- Video -Chilli Pickling...

Session 3.10

Practice

- Drying of Apple and Pineapple Slices using Cabinet Dryer

- PDF -Practical 10 Drying of Fruits and Vegetables...

- Video -Dried Fruit...

Session 3.11

Practice

- Drying of Fruits and Vegetables using Freeze Dryer

- Video -Freeze Drying of Food...

Session 3.12

Practice

- Processing of Foods - Fermentation and Preparation of Sauerkraut

- PDF -Practical 11 Preparation of Sauerkraut...

- Video -Preparation of Sauerkraut...

Session 3.13

- Hands on Training in Gram Tarang Foods

- Jelly Preparation...

4. Product Development and Processing Technologies

Session 4.1

Product Development Strategy

- PDF -Product Development Strategy...

- Session 4.1_ Introduction to Cereal Grains Milling Operations...

- Video -Reasons for New Products...

- Video -Reasons for New Food Product - Consumer Concerns...

Session 4.2

Session 4.3

Product Design Development

- PDF -Product Design Development...

- Session 4.3 – Wheat, Corn, Oats Milling...

- Video -Stages of Product Development...

Session 4.4

Process Development

- PDF -Process Development...

- Session 4.4 – Pulse Milling...

- Video -Product Formulations and Process Development...

Session 4.5

Product Testing

- PDF -Product Testing...

- Session 4.5 – Technology of Bread Making...

- Video -Shelf Life Testing of Food Products...

Session 4.6

Product Commercialization

- PDF -Product Commercialization...

- Session 4.6 – Technology of Biscuit Making...

- Video -Coca Cola Strategy...

Session 4.7

Product Launch and Evaluation

Session 4.8

Future of product Development Process

- PDF -Future of Product Development...

- Session 4.8 – Oil Extraction Technology...

- Video -Future of Food - 2025...

Session 4.9

Product Development - Examples

- Session 4.9 – Packaging Technology...

- Video -Product Development - Beverages...

- Video -Product Development - Dairy...

- Video -Pulses Replacing Eggs and Dairy...

- PDF -Product Development for Gut Microbiome

Session 4.10

Deteriorative Reaction in Foods

Session 4.11

Shelf Life of Food

Session 4.12

Food Packaging Closure and Sealing Systems

Session 4.13

Packaging of Horticultural Products

- PDF - Packaging of Horticultural Products...

- Video -Active Packaging to Extend Shelf Life of Fruit...

Session 4.14

Packaging of Cereals, Snack and Confectionery Foods

- PDF - Packaging of Cereal and Millet based Products...

- Video -How Skittles are Made...

- Video -Manufacturing of Kitkat...

Session 4.15

Packaging of Dairy Products

- PDF - Packaging of Dairy Products...

- Video -Milk Bottling Line...

Session 4.16

Packaging of Beverages

- PDF - Packaging of Beverages...

- Video -Coca - Cola Manufacturing...

Session 4.17

Modified Atmospheric Packaging

- PDF - Modified Atmosphere Packaging...

- Video -MAP...

- Video -MAP -2...

Session 4.18

Active and Intelligent Packaging

Session 4.19

Aseptic Packaging of Foods

- PDF - Aseptic Packaging of Foods...

- Video -Aseptic Packaging...

5. Food Standards and Regulations and HACCP Systems

Session 5.1

Codex Alimenatarius

- Website -Codex Alimentarius - International Standards

- TQM...

- CODEX Alimentarius...

- Video -CODEX and the Food we Eat...

- PDF -Labelling Standards for Mango Chutney...

Session 5.2

ISO Standards for Food Safety Management

- Website -ISO

- PDF -ISO - Food Safety Management

Session 5.3

Safe Quality Food (SQF)

- Website -One World One Standard

- PDF -SQF Certification Guide...

Session 5.4

Global Food Safety Initiative

Session 5.5

Total Quality Management

- TQM...

- Website -Total Quality Management...

Session 5.6

Food Hygiene

Session 5.7

Food Safety Standards Authority of India

Session 5.8

Bureau of Indian Standards

- Bureau of Indian Standards (BIS)...

- Website -BIS

Session 5.9

AGMARK Certification

Session 5.10

Agricultural and Processed Food Products Export Development Authority

Session 5.11

Spices Board India

Session 5.12

HACCP

Session 5.13

Pre HACCP Activities and Pre-requisite Programs

- PDF -Pre-HACCP Activities...

- PDF -Prerequisites - GMP and SOP...

- Video -Pre-requisite Programs...

- Video -GMP's...

Session 5.14

SSOP'S and GMP'S

- Video -SSOP...

- Video -10 Principles of GMP's...

Session 5.15

HACCP Team

- PDF -HACCP Team...

Session 5.16

Hazard Analysis

- Hazards in Foods...

- HAZARD ANALYSIS...

- Principle 1 Hazard Analysis...

- Video -Hazard Types...

- Video -Hazard Analysis...

Session 5.17

Identify Critical Control Points

- Principle 2 Identifying CCPs...

- Video -CCP's...

- Video -Identify CCP...

Session 5.18

Establish Critical Limits

Session 5.19

Establish Monitoring Procedures

Session 5.20

Establish Corrective Actions

Session 5.21

Establishing Verification Procedures

Session 5.22

Establishing Record-keeping and Documentation Procedures

Session 5.23

HACCP Comprehensive

- Video -HACCP Guide...

6. Sensory Evaluation and Nutritional Labelling of Products

Session 6.1

Sensory Evaluation - Brief Background

Session 6.2

Sensory Evaluation - Experimental Design and Procedures

- PDF - Sensory Testing Protocol ...

- Video -Sensory Lab...

Session 6.3

Discrimination Tests

- PDF -Discrimination Tests ...

- Video -Techniques in Sensory Evaluation...

- Video -Duo-Trio Test...

- Video -Hedonic Scale...

Session 6.4

Sensory Thresholds

- PDF -Sensory Thresholds ...

- Video -Threshold for Taste...

Session 6.5

Descriptive Analysis

- PDF -Descriptive Analysis ...

- Video -Descriptive Panel...

Session 6.6

Flavour and Texture Analysis

- Video - Science of Flavour...

- PDF -Texture Evaluation ...

- Video -Texture of Bread...

- Video -Texture Profile Analysis...

Session 6.7

Evaluation of Colour and Appearance

Session 6.8

Consumer Questionnaire - Field Tests

- PDF -Consumer Questionnaire...

- Video -Consumer Panel...

Session 6.9

Statistical Concepts for Sensory Analysis

- PDF - Sensory Analysis_Statistical Concepts ...

- Video -ANOVA...

Session 6.10

Test Sensitivity

Session 6.11

Food Labelling

Session 6.12

Nutrient Labelling

- PDF -Nutrition Labelling Facts ...

- Video -Label Reading...

- Video -Reading Label...

Session 6.13

Labelling Claims

- Video -Labelling Claims...

- Video -GMO Identification...

- Video -Reading Organic Label...

- Video -Are Food Labels a Scam...

- Video -Added Sugars - Health Claim...

Session 6.14

Calorie Calculations

- Video -Calorie Information...

- Video -How to Count Calories...

Session 6.15

FSSAI Labelling Standards

Session 6.16

CODEX Guidelines

Session 6.17

Nutrient Labelling Going Forward

- PDF -Nutrition Labelling Challenges ...

- PDF -Food and Nutrition Labelling - Past, Present and Way Forward ...

- Video -New Nutrition Facts Label...

Session 6.18

Creating Nutrition Label

- Video -Nutrition Label...

- Video -Software for Dietary Calculations...

Latest News & Student Testimonials

Media

Our Main Teachers

Qualification: Ph.D. (IIT Kharagpur, West Bengal) M.Tech (Anna University, Chennai) B.Tech (Shri Mata Vaishno Devi University, J & K) Area of Specialization: Food Technology, Food Processing Research Interest: Agri-waste utilization, Green Extraction Technologies Subjects Teaching: Processing Technology of Fruits, Vegetables, Spices and Condiments Product Development & Packaging Technology

Dr. Kakani has a PhD in Food Science and Technology, an MS (Food Science and Technology) with emphasis on food microbiology, and MAB (Master in Agribusiness Management) from Texas A&M University, College Station, USA. She holds a bachelor’s degree in Agricultural Sciences from Acharya NG Ranga Agricultural University, Hyderabad. She specializes in the area of […]

Qualification: Ph.D (IIT Kharagpur) M. Tech (OUAT, Bhubaneswar) B. Tech (OUAT, Bhubaneswar) 40 years of teaching and research experience Area of Specialization: Food Process Engineering Research Interest: Agricultural By-products utilization Development of Process Technologies Development of post-harvest equipment Email: [email protected] Phone: 7989927565 Subjects Teaching: Processing Technology of Cereals and Millets CUFP2310(1-2-0)

Educational Qualification :- Ph.D. (Odisha University of Agriculture and Technology, Bhubaneswar) M.Tech. (Jawaharlal Nehru KrishiVishwavidyalaya, Jabalpur, M.P) B.Tech. (Indira Gandhi KrishiVishwavidyalaya, Raipur, Chhattisgarh) Area of Specialization: Engineering Properties of Biological Materials; Processing and food engineering, Post-Harvest processing of cereal pulses and storage Engineering. Drying studies and characteristics of agricultural produce. Research Interest: Isolation of starch […]

Qualification: Ph.D (IITKharagpur), M. Tech (IIT Kharagpur, B. Tech (Jawaharlal Nehru KrishiVishwavidyala, Jabalpur) Area of Specialization: Food Process Engineering Research Interest: Cereal Processing, Microwave heating, Drying Email: [email protected] Phone: +91-8101766639 Subjects Teaching: Processing Technology of Legumes and Oilseeds CUFP2311(1-2-0) Sensory Evaluation and Nutritional Labelling of Foods CUFP2315(0-3-0)