The domain Fish Processing Technology empowers the students to understand novel technologies applied in processing for product development of dry fish, salted and smoked fish, frozen fillets, mince based products like surimi, ham and sausage using fish deboner and mincer equipments and did packaging using vacuum packaging machine. Knowledge on Fish byproduct valorization into value added products such as silage, fish protein hydrolysate, chitin, chitosan and collagen. Besides value added fish products, the domain provides hands on experience on quality asessment of fish and fishery products using microbiological techniques like, TPC, identification of fish spoilage organism like S. aureus, E. coli, C. botulinum etc, and biochemical techniques like, Proximate composition, TMA, TVB-N, TBARS and PV. Students also experienced educational visits to top fish processing and training institutes like ICAR-CIFT and NIFPHATT. This domain makes students technically skilled and ready for career placement in industries and companies like fish and shrimp processing, research institutes, R&D departments, food processing industries, food quality analysis laboratories. Students also developed entrepreneur skills through this domain.

Domain Track: Fish Processing Technology

Course Attendees

Still no participant

Course Reviews

Still no reviews

Fish are highly valuable but easily perishable item. An immediate action after harvest is required in order to preserve the quality. Students learned how to slow down spoilage immediately after the harvest depending on type of fish i.e. finfish, shellfish. Muscle structure, factors affecting quality of fresh fish and shellfish. When the course is complete, students will be skilled with different processing style of finfish and shellfishes (fillets, head-on, tail-on etc). Importance of refrigerated storage and cold chain in preservation of fish. The objective is significant for seeking job in a fish processing plant, quality control lab., Self employment, Export and import Agencies. Students will understand the fundamentals of processing plant design, site selection, design and preparation of layout of processing plants - freezing plant, cold storage, canning plant, dryers etc. Safety controls for freezing and canning plant effluent treatment: Legislation and standards of effluent discharge, water pollution control measures in the food industry. This experienced will help in seeking job in a fish processing plant, quality control laboratory and research institutes. Students are involved in skilled based learning in preparation of different products from fish and shellfish that are ready-to-eat and ready-to-cook. The importance of hygiene and sanitation during the production process. This skilled forms a basic experienced when looking for an appointment in fish processing plant, quality control laboratory, self employed and R&D departments, export and import Agencies. Students gained the experienced for the utilization of fish waste like skin, scale, bones, shells etc and used for production of valuable products like, gelatin, fish oil, fish silage, chitin and chitosan etc. These skilled forms a basis experienced when looking for an appointment in fish processing plant, quality control laboratory. Students gets a hands-on experienced in the quality parameters required to estimate the quality of the fish and fisheries products, physically- sensory evaluation, biochemical parameters like proximate composition, TMA, TVBN, TBARS and microbiologically enumeration of bacterial, isolation and identification of bacteria flora, bacterial staining. This skill is important when seeking job in a fish and food processing plant, quality control laboratory, Research institutes, Export and import Agencies.Track Total Credits ( T-P-P): (3-12-11) (26 Credits)

Courses Division( list all divisions):

Domain Track Objectives:

To teach various post-harvest changes and handling of fish and shellfish.

To teach plant design, function and maintenance of fish processing plants and safety standards.

To teach scientific techniques of fish processing and value addition.

To teach students regarding various fish and shellfish by-products, and their utilization.

To learn physical, biochemical and microbiological properties in fish and fisheries products.

Domain Track Learning Outcomes:

Career Scope:

Domain Syllabus:

Course 1: Post-harvest handling and processing of fish and shellfish (1-1-0)

Theory:

- 1.1. Handling of fish and shellfish on-board fishing vessels, Unit operations, loading and unloading of fish and shellfish.

- 1.2. Post-harvest fishery losses, methods to reduce losses, handling of fish and shellfish in landing centres, defects and modifications needed.

- 1.3. Different types of ice used in storage of fish and shellfish, storage methods.

- 1.4. Physical, chemical, microbiological and sensory changes during handling, chill storage, iced and refrigerated storage of fishes.

- 1.5. Structure of fish and shellfish myosystems, Post-mortem changes of fish and shellfish after harvesting.

- 1.6. Factors affecting quality of fresh fish and shellfish-intrinsic and extrinsic factors.

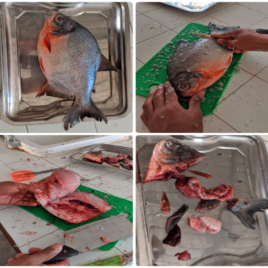

- 1.7. Pre-processing and filleting of fish, Processing of prawns, lobster, squid, cuttle fish, crab,depuration of bivalves, etc.

- 1.8. Transportation of live fish/shell fish, Transportation of raw fish to local markets and processing centres,

- 1.9. Refrigerated transport systems, Cold chain,Improvements needed in transportation and handling of fish and shellfishes.

Practical:

- 1.1. Depuration, bleeding, deveining of fish and shellfish.

- 1.2. Pre-processing and use of potable water in fish and shellfishes.

- 1.3. Different processing and cutting style of finfishes.

- 1.4. Different processing style of shellfishes (prawns, shrimps, lobster, and crab).

- 1.5. Processing style of squid, cuttle fish, bivalves, etc.

- 1.6. Storage, preservation, andtreatment with natural bio preservative, organic acid and chemical agent.

- 1.7. Determination of shelf life of fish and shellfish

- 1.8. Heat load calculation of ice requirement in finfish and shellfish.

- 1.9. Chemical, physical and sensory freshness analysis of fish and shellfishes.

Course 2: Design, maintenance of fish processing plant and instrumentation (1-1-0)

Theory

- 2.1. Fundamentals of processing plant design, Site selection, design and preparation of layout of processing plants - freezing plant, cold storage, canning plant, dryers etc.

- 2.2. Functions and construction of refrigeration system, Tests and inspection, Operation and handling.

- 2.3. P-H diagram and basic calculation - Application of P-H diagram, size and required power of compressor, maintenance of refrigerating machine, troubles and causes.

- 2.4. Preventive maintenance of machinery and equipment of fish processing plants, IQF, Canning plant, sausage plant, artificial dryers, smoking chambers etc.,

- 2.5. Safety controls for freezing and canning plant effluent treatment: Legislation and standards of effluent discharge, water pollution control measures in the food industry.

- 2.6. Waste water treatment process; dissolved air floatation, sedimentation, chemical treatment, biological treatment, aeration, carbon adsorption, granular media filtration and sludge handling.

- 2.7. Boilers - Classification and selection of boilers, Boiler mounting and accessories.

- 2.8. Measurement techniques Sensors, active and passive sensors, characteristic of sensors for the measurement of temperature, relative humidity, aw value, gel strength, moisture, freshness, pH, conductivity, DO, redox potential, salinity, air velocity, solar energy and brine concentration.

- 2.9. Different types of thermometers, characteristics and application. Instrumentation techniques: General configuration of instrumentation system. Instrumentation for measurement of aw value, temperature, pH, freshness, gel strength, salinity, brine concentration.

- 2.10. Thermal properties of foods, Calorie, heat loss, heat gain, specific heat, Newton's laws of cooling, heat transfer, latent heat, laws of fusion, thermal conductors, and thermal diffusivity.

Practical:

- 2.1. Design and Maintenance of Fish Processing Plants.

- 2.2. Operation and maintenance of machinery and equipment for cold storage plant, freezing plant, canning plant, sausage making, dryers, boilers etc.

- 2.3. Assembly of a refrigeration unit and charging refrigerant.

- 2.4. Measurement of temperature inside cold storage / freezer, fish during freezing and thawing.

- 2.5. Estimation of Gel strength.

- 2.6. Measurement of solar radiation, air velocity, air temperature.

- 2.7. Measurement of salinity, conductivity, pH.

- 2.8. Estimation of water activity.

- 2.9. Field visit to fish/shrimp processing plant.

Course 3. Quality assurance, management and certification (1+1+0)

Theory:

Quality management, total quality concept and application in fish trade.

- 3.1. Quality assessment of fish and fishery products - physical, chemical, organoleptic and microbiological quality standards.

- 3.2. Inspection and quality assurance

- 3.3. Water Quality and standards : water analysis, treatments, chlorination, ozonisation, UV radiation, reverse osmosis, techniques to remove pesticides and heavy metals.

- 3.4. Sensory evaluation of fish and fish products: Basic aspects, different methods of evaluation, taste panel selection and constitution, statistical analysis.

- 3.5. HACCP and Quality problem in fishery products: Good manufacturing practices, HACCP Principles, Practical aspects of planning and implementation, verification, validation and Audit.

- 3.6. National and international standards: ISO 9000:2000S series of quality assurance system, Codex alimentarius, USFDA and EU regulations for fish export trade, IDP and SAT formations in certification of export worthiness of fish processing units, regulations for fishing vessels, pre-processing and processing plants, EU regulations, ISO 22000:2006

- 3.7. Factory sanitation and hygiene: National and international requirements, SSOP, Sanitary and phytosanitary measures.

- 3.8. Water quality and standards: water analysis, purification and treatment of water.

- 3.9. Food laws in India, integrated food law.

Practical:

- 3.1. Evaluation of fish / fishery products for organoleptic, chemical and microbial quality.

- 3.2. Methods for analysis for bacterial quality parameters, chemical parameters and filth.

- 3.3. Evaluation of sanitary conditions in fish processing units.

- 3.4. Analysis of typical hazards. Study of correction and corrective action.

- 3.5. Filling procedure for licensed/certification for BIS, FSSAI,HACCP

- 3.6. SQC: Introduction, statistical principles involved, process control, control charts, variable and attribute control charts, Acceptance sampling, basic ideas, sampling by attributes single and double sampling plants, Basic concepts of decision making.

- 3.7. Familiarization with water quality analysis.

Course 4: Fish and shellfish waste management (0+3+0)

Practical:

- 4.1. Fish meal Production –by using dry and wet rendering process, machinery, control of quality of products, specifications, packaging and storage.

- 4.2. Fish body and liver oils extraction, purification, preservation and storage,

- 4.3. Fish protein concentrate (FPC): different methods of production, functional properties and types of FPC.

- 4.4. Fish silage preparation, Acid silage and fermented silage, advantages over fish meal, nutritional value of silage.

- 4.5. Fish hydrolysates: Production and utilization, biochemical composition and importance in food and nutrition.

- 4.6. Shrimp waste, crab shell and squilla utilisation: Conventional uses, feeds and manure formation,

- 4.7. Extraction of chitin, chitosan and glucosamine hydrochloride from crustacean shell waste.

- 4.8. Commercial production and use of protein isolates from squilla and shrimp waste.

- 4.9. Preparation of by-products: Fish maws, isinglass, collagen, and gelatin.

- 4.10. Preparation of pearl essence from fish scale waste,

- 4.11. Production of fertilizer, fish glue etc.

- 4.12. Processing of snail meat.

5. Microbiological analysis of fish and fisheries products: (0+3+0)

Practical:

- 5.1. Sampling and processing of samples for microbiological investigation.

- 5.2. Enumeration of microorganisms associated with finfish, shellfish, water and ice.

- 5.3. Techniques in sterilization: Physical and chemical methods of sterilization, Preparation of media.

- 5.4. Safety in microbiology laboratory: Prevention of contamination, Biosafety level, disinfection methods

- 5.5. Microscopy: Bright field, phase contrast

- 5.6. Stains, Staining methods

- 5.7. Laboratory Biochemical techniques to detect and isolate pathogens in fish:E.coli, Staphylococcusaureus, Streptococusfaecalis, Clostridium perfrigens, Clostridium botulinum, Salmonella,Listeria, Vibrio cholera, Vibrio parabaemolyticus, V. Vulnificus,

- 5.8. Preservation and maintenance of cultures

- 5.9. Testes for identification of bacteria: Phenotypic, cultural, and serological techniques

- 5.10. Culture of Anaerobic bacteria

- 5.11. Identification of fungi from fish and Fishery Product

- 5.12. Bio-assay of bacterial toxins.

- 5.13. Antibiotic assay: sensitivity tests, evaluation of antibacterial properties.

- 5.14. Analysis of fishproduct constituents: MIC, MCC, Methods for Risk analysis of seafood.

- 5.15. Basics of Molecular techniques: Rapid identification of bacteria

- 5.16. Basics of virological techniques.

6. Biochemical analysis of fish and fisheries product (0+3+0)

- 6.1 Proximate composition of fish products

- 6.2. Qualitative determination of Carbohydrates

- 6.3. Qualitative determination of proteins and amino acids

- 6.4,Qualitative determination of lipids.

- 6.5. Estimation of Total Volatile Basic Nitrogen (TVBN)

- 6.6.Estimation of Trimethylamine (TMA) Nitrogen

- 6.7. Estimation of Thiobarbituric Acid (TBA) value

- 6.8.Estimation of Peroxide Value

- 6.9. Determination of Free Fatty Acid Value

- 6.10. Estimation of Salt (Sodium Chloride)

- 6.11. Determination of Saponification Value

- 6.12. Determination of Specific Gravity of Oil.

- 6.13. Determination of Iodine Value

- 6.14. Sensory evaluation of fish product using 9 point hedonic scale.

- 6.15. Measuring responses- difference tests, triangle test, Duo-trio, and other tests, attribute difference tests.

7. Preparation of different fisheries products and quality assessment (0+0+11)

Business planning and designing, Preparation of value added fish product, nutritional quality and biochemical properties assessment.

Suggested Books:

- Post-harvest Technology of Fish and Fish Products- K.K. Balachandran

- Advances in Fish Processing Technology By D.P. Sen

- Seafood Quality by C.I.F.T

- Laboratory Manual in General Microbiology-Dr. N. Kannan

- Kanduri L & Eckhartt RA. 2002. Food Safety in Shrimp Processing. Fishing News Books

- Shukla RK. 2006. Total Quality Management Practicing Manager. New Royal Book

Session Plan for the Entire Domain: Fish Processing Technology

Course 1: Post-harvest handling and processing of fish and shellfish (1-1-0)

Theory

Session 1

Session 2

- 1.2 Handling Of Fish In Landing Centres defect and modification needed...

- 1.2.1Reducing Post-harvest fish losses for improved Food security...

- Video Link ...

Session 3

- 1.3 Different types of ice and their manufacture...

- 1.3.1 Popularization of fresh fish cutting style for value addition in processing industry...

- Lecture Video Link ...

Session 4

Session 5

Session 6

Session 7

- 1.7 Pre-processing and filleting of fish...

- 1.7.1 Processing of shrimp prawn and crab...

- 1.7. 2 Preparation of squid, cuttlefish and octopus...

- 1.7.3 Depuration of bivalve...

- Video Link 1...

- Video Link 2...

- Video Link 3...

Session 8

Session 9

Practice

Session 10

Session 11

Session 12

- 12 Popularization of fresh fish cutting style for value addition in processing industry...

- Video Link ...

Session 13

Session 14

Session 15

Session 16

Session 17

Session 18

Course2: Design, maintenance of fish processing plant and instrumentation (1-1-0)

Theory

Session 1

Session 2

Session 4

Session 5

Session 6

Session 7

Session 8

Session 9

Session 10

Practice

Session 11

Session 12

- 2.12 Operation and maintenance of machinery equipment for cold storage and canning plant...

- Video Link ...

Session 13

Session 14

Session 15

Session 16

Session 17

Session 18

Session 19

- Field visit to Fish/Shrimp Processing plant.

COURSE: 3. Quality assurance, management and certification (1+1+0)

Theory

Session :1

- 3.1.Quality management, total quality concept and application in fish trade.

- Introduction to Quality Management and Applications ...

- Video link ...

Session: 2

- Quality assessment of fish and fishery products - physical, chemical, organoleptic and microbiological quality standards.

- 3.1. Quality assessment of fish and fishery products - physical, chemical, organoleptic and microbiological quality standards...

- Video link ...

Session: 3

- Inspection and quality assurance: Fish inspection in India, process water quality in fishery industry, product quality.

- 3.2. Inspection and quality assurance: Fish inspection in India, process water quality in fishery industry, product quality...

- Video link ...

- Video Link ...

Session: 4

- Water Quality and standards : water analysis, treatments, chlorination, ozonisation, UV radiation, reverse osmosis.

- 3.3. Water Quality and standards : water analysis, treatments, chlorination, ozonisation, UV radiation, reverse osmosis ......

- Video link 1...

- Video link 2...

Session: 5

- 3.4. Sensory evaluation of fish and fish products

- 3.4. Sensory evaluation of fish and fish products...

- Video link ...

Session: 6

- 3.5. HACCP and Quality problem in fishery products

- 3.5. HACCP and Quality problem in fishery products...

- Video link ...

Session: 7

- 3.6. National and international standards

Session: 8

Session: 9

Session: 10

Session: 11

- 3.7. Factory sanitation and hygiene

- 3.7. Factory sanitation and hygiene...

- Video link ...

Session: 12

3.8. Water quality and standards

Session: 13

- Food laws in India

- 3.9. Food laws in India...

- Video link ...

Practice

Session: 1

- 3.1.Evaluation of fish / fishery products for organoleptic, chemical and microbial quality.

- Practical 3.1. Evaluation of fish / fishery products for organoleptic, chemical and microbial quality...

- Video link ...

Session: 2

-

- 3.2. Methods for analysis for bacterial quality parameters, chemical parameters

- Practical 3.2. Methods for analysis for bacterial quality parameters, chemical parameters...

Session: 3

- Practical 3.2.(1). Methods for analysis for bacterial quality parameters, chemical parameters...

- Video link ...

- Video link ...

Session: 4

- Evaluation of sanitary conditions in fish processing units

- Practical 3.3. -Evaluation of sanitary conditions in fish processing units...

- Video link ...

Session: 5

- Analysis of typical hazards. Study of correction and corrective action

- Practical 3.4. Analysis of typical hazards. Study of correction and corrective action...

- Video link ...

- Video link ...

Session: 6

- Filling Procedure for Licensed/certification for HACCP

- Practical 3.5. Filling Procedure for Licensed/certification for HACCP...

- Video link ...

- Video link ...

Session: 7

- Introduction, statistical principles involved, process control, control charts, variable and attribute control charts, Acceptance sampling, basic ideas, sampling by attributes

- Practical 3.6. Introduction, statistical principles involved, process control, control charts, variable and attribute control charts, Acceptance sampling, basic ideas, sampling by attributes ...

Session 8

- Practical 3.6.1. Introduction, statistical principles involved, process control, control charts, variable and attribute control charts, Acceptance sampling, basic ideas, sampling by attributes...

- Video link ...

- Video link ...

Session: 9

- Familiarization with water quality analysis

- Practical 3.7. Familiarization with water quality analysis...

- Video link ...

Course 4. Fish and shellfish waste management(0+3+0)

Practical

Session 1

- 4.1. Fish meal Production –by using dry and wet rendering process, machinery, control of quality of products, specifications, packaging and storage.

- 4.1.FISH-MEAL...

- 4.1.Special Methods of Processing...

- 4.1.FISH MEAL PROCESSING

- Video Link ...

Session 2

- 4.2. Fish body and liver oils extraction, purification, preservation and storage.

- 4.2. FISH OIL...

- 4.2. FISH OILCIRC277...

- 4.2.Fish-Oil...

- Video Link ...

Session 3

- 4.3. Fish protein concentrate (FPC): different methods of production, functional properties and types of FPC.

- 4.3. FPC1...

- 4.3.FPC...

- Video Link 1...

- Video Link 2...

- Video Link 3...

Session 4

- 4.4. Fish silage preparation, Acid silage and fermented silage, advantages over fish meal, nutritional value of silage.

- 4.4. CIWAFish-SilageTechnology...

- 4.4. Fish-silage...

- Video Link ...

Session 5

- 4.5. Fish hydrolysates: Production and utilization, biochemical composition and importance in food and nutrition.

- 4.5. PARTIALLY-HYDROLYSED-AND-DEODORISED-FISH-MEAL...

- 4.5. Protein Hydrolysate from Miscellaneous fish...

- 4.5.FPH...

- Video Link ...

Session 6

- 4.6. Shrimp waste, crab shell and squilla utilisation: Conventional uses, feeds and manure formation.

- 4.6. chitin fromcrab shell...

- Video Link ...

- Video Link ...

Session 7

- 4.7. Extraction of chitin, chitosan and glucosamine hydrochloride from crustacean shell waste.

- 4.7.CHITIN...

- 4.7.Chitosan-Usage...

- 4.7. Chitiosan...

- 4.7.Chitin...

- Video Link 1...

- Video Link 2...

- Video Link Chitin Bioplastick...

- Video Link Chitosan Bioplastic...

Session 8

- 4.8. Commercial production and use of protein isolates from squilla and shrimp waste.

- 4.8. Protein isolate from squilla...

Session 9

- 4.9. Preparation of by-products: Fish maws, isinglass, collagen, and gelatin.

- 4.9. gelatin-160514183043...

- 4.9. Production of food grade gelatin...

- 4.9. Production of Isinglass...

- 4.9.Fish-glue-gelatin-isinglass-pearl-essence...

- 4.9. Fish maws and Isinglass...

- Video Link ...

- Video Link ...

- Video Link- Isinglass ...

Session 10

- 4.10. Preparation of pearl essence from fish scale waste.

- 4.10. pearl essence...

- 4.10.PREPARATION-OF-PEARL-ESSENCE...

Session 11

- 4.11. Production of fertilizer, fish glue etc.

- 4.11. Fish glue...

- Video Link ...

- Video Link ...

Session 12

- 4.12. Processing of snail meat.

- 4.12 Processing of snail meat...

- Video Link ...

Course 5: Microbiological analysis of fish and fisheries products: (0+3+0)

Practical

Session : 1

- Sampling and processing of samples for microbiological investigation

- 5.1 Sampling and processing of samples for Microbiological investigation...

- Video Link ...

Session : 2

- Enumeration of microorganisms associated with finfish, shellfish

- 5.2 Enumeration of Microorganisms in foods...

- Video Link ...

Session : 3

- Techniques in sterilization: Physical and chemical methods of sterilization, Preparation of media.

- 5.3 Media preperation...

- Video Link ...

Session: 4

- Techniques in sterilization: Physical and chemical methods of sterilization, Preparation of media.

- 5.3.1 Sterilization techniques...

- Video Link ...

Session: 5

- Safety in microbiology laboratory

- 5.4 Safety in microbiology laboratory...

- Video Link 1...

- Video Link 2...

Session: 6

-

- Microscopy: Introduction

- 5.5 Microscopy...

Session: 7

- Microscopy: Bright field

- 5.5 microscopy (2)...

- Video Link ...

Session: 8

- Microscopy: Phase contrast

- 5.5 Microscopy (3)...

- Video Link ...

Session: 9

- Stains, Staining methods

- 5.6 Stains and staining ...

- Video Link ...

Session: 10

- Stains, Staining methods

- 5.6.1 Stains and Staining methods...

- Video Link ...

Session: 11

- Laboratory Biochemical techniques to detect and isolate pathogens in fish

- 5.7. Biochemical tests ...

- Video Link ...

Session: 12

- Preservation and maintenance of cultures

- 5.8. Preservation and Maintenance of culture...

- Video Link ...

Session: 13

- Laboratory Biochemical techniques to detect and isolate pathogens in fish

- 5.7. Biochemical tests (1)...

- Video Link ...

Session: 14

- Laboratory Biochemical techniques to detect and isolate pathogens in fish

- 5.7. Biochemical tests (2)...

- Video Link ...

Session: 16

- Culture of Anaerobic bacteria

- 5.10. Anaerobic culture method...

- Video Link ...

Session: 17

- Identification of Fungi from Fishery Products

- Fungi Fundamentals and diagnosis...

- Video Link ...

Session: 18

- Bio-assay of bacterial toxins

- 5.12. bioassay on bacterial toxins...

- Video Link ...

Session: 19

- Antibiotic assay

- 5.13. aNTIBIOTIC ASSAY...

- Video Link ...

Session: 20

- Analysis of fish product constituents

- 5.14.Determination of MIC and MCC...

Session: 21

- Molecular identification of Bacterial strains

- 5.14. Molecular bacterial identification...

- Video Link ...

Session: 22

- Virological techniques

- 5.15 virological technique...

- Video Link ...

Course 6. Biochemical analysis of fish and fisheries product (0+3+0)

Practical

Session 1.

- Proximate composition of fish products

- 6.1. Ash...

- 6.1. Carbohydrates...

- 6.1. Fibre...

- 6.1. Lipid...

- 6.1. protein...

- 6.1. Alpha-amino nitrogen...

- Video Link Protein ...

- Video Link lipid ...

- Video Link Fibre ...

- Video Link Carbohydrates ...

Session 2.

- 6.2. Qualitative determination of Carbohydrates

- 6.2. Qualitative analysis of carbohydrates...

- Video Link ...

- Video Link ...

Session 3.

- Qualitative determination of proteins and amino acids.

- 6.3. Qualitative analysis of protein and amino acids...

- Video Link ...

- Video Link ...

Session 4.

- Qualitative determination of lipids.

- 6.4. Qualitative analysis oflipids...

- Video Link ...

Session 5.

- Estimation of Total Volatile Basic Nitrogen (TVBN)

- 6.5. TVBN...

- Video Link ...

Session 6.

- Estimation of Trimethylamine (TMA) Nitrogen

- 6.6. TMA...

- Video Link ...

Session 7.

- Estimation of Thiobarbituric Acid (TBA) value

- 6.7. TBARS ...

- Video Link 1...

- Video Link 2...

Session 8.

- Estimation of Peroxide Value

- 6.8. PV...

- Video Link ...

Session 9.

- Determination of Free Fatty Acid Value

- 6.9. FFA...

- Video Link ...

Session 10.

- Estimation of Salt (Sodium Chloride)

- 6.10. SALT...

- Video Link ...

Session 11.

- Determination of Saponification Value

- 6.11. SAPONIFICATION VALUE...

- Video Link ...

Session 12.

- Sensory evaluation of fish product using 9 point hedonic scale.

- 6.14. SENSORY EVALUATION...

- Video Link ...

Session 13.

- Determination of Iodine Value

- 6.13. IODINE VALUE...

- Video Link ...

Session 14.

- Determination of Specific Gravity of Oil.

- 6.12. SPECIFIC GRAVITY...

- Video Link ...

Session 15.

- Measuring responses- difference tests, triangle test, Duo-trio, and other tests, attribute difference tests.

- 6.15 measuring test...

- Video Link ...

- Video Link duo and triangular ...

Media

Our Main Teachers

Dr. AmruthaGopan has been working as Assistant Professor at School of Fisheries, CUTM, Parlakhemundi, Odisha, since 2019. She completed her Ph.D. in Fish Nutrition and Feed Technology in 2020 from ICAR-Central Institute of Fisheries Education, Mumbai. She secured M.F.Sc.(Master of Fisheries Science) in Fish Nutrition and Feed Technology in 2015 from the same institute.She graduated […]