Explores detailed insights on cutting-edge technologies of dairy processing unit operations leading to dairy manufacturing, product development and quality and safety assessment of milk and milk products

Domain Track: Dairy Processing and Development

Course Attendees

Still no participant

Course Reviews

Still no reviews

Credits (T-P-P): 3-15-10 (28 credits)

Courses Division:

- Milk Processing in Dairy Industry (1+2+0) (CUDP2240)

- Dairy Starters in Fermented Milk Products (1+2+0) (CUDP2241)

- Quality Assurance in Dairy Industry (1+2+0) (CUDP2242)

- Dairy Products Development (0+3+0) (CUDP2243)

- Synbiotic Dairy Foods (0+3+0) (CUDP2244)

- Quality Analysis of Milk and Milk Products (0+3+0) (CUDP245)

- Project & Industrial Internship (0+0+10) (CUDP2246)

Domain Track Objectives:

The domain will accustom students about the processing of raw milk besides, developing skills to handle unit operations and dairy processing machineries. Furthermore, it also aspires to provide hands-on experience to prepare different types of dairy products, overview on starter cultures, probiotics and synbiotic dairy foods as well as evaluate quality of milk and milk products. Overall, the track targets to assign some credits to students to perform their project work under supervision of departmental faculties.

- To acquaint students about the processes involved in the processing of raw milk with constructional details, operation and maintenance of dairy equipment.

- To impart a comprehensive knowledge on dairy starters for the production of health beneficial fermented foods.

- To apprise students with the quality control and safety of milk and milk products.

Domain Track Learning Outcomes:

- Able to prepare standardized milk as well as able to handle and maintain equipment related to raw milk processing.

- Implement improvement strategies on developing better dairy starters for the production of fermented foods with therapeutic properties.

- Detect adulterants, preservatives and neutralizers in milk and milk products.

Career Scope:

- Food Safety Officer

- Milk Procurement Officer

- Dairy Extension Officer

- QA/QC Executive/Manager

- Logistics and Distribution Manager

- Dairy Plant Manager/Technical Officer

- Dairy Consultant

- Dairy Entrepreneur

- Research and Development

- Government and semi-government organizations

Domain Syllabus:

1. Milk Processing in Dairy Industry (1+2+0) (CUDP2240)

Theory

- 1.1. Collection and Transportation of milk: Organization of milk collection routes, practices for collection of milk, preservation at farm, refrigeration, natural microbial inhibitor, reception, chilling, classification and storage.

- 1.2. Standardization of milk: Addition or removal of milk fat to make different milk products, numericals.

- 1.3. Mechanical Separation: Sedimentation, Filtration, Centrifugal separation, Bactofugation.

- 1.4. Homogenization: Classification, power requirement, care and maintenance

- 1.5. Pasteurization: Batch, flash and HTST pasteurization

- 1.6. Packaging machines: Pouch filling machine pre-pack and aseptic filling bulk handling system

- 1.7. Mixing and agitation: Theory and purpose of mixing, Equipment used

- 1.8. Evaporation: Basic principles and classification

- 1.9. Drying: Drum drying, Spray drying

- 1.10. Membrane processing: Ultrafiltration, Reverse Osmosis and electrodialysis, Materials for membrane construction, Ultrafiltration of milk, Effect of milk constituents on operation, membranes for electro-dialysis.

Practice

- 1.1. Familiarization with equipments for reception of milk in plant, platform test.

- 1.2. Cream separation: parts of a separator and the process.

- 1.3. Preparation of special milk: toned and double toned milk.

- 1.4. Detection of adulterants and preservatives in milk.

- 1.5. Constructional details, operation and maintenance of homogenizers.

- 1.6. Assessment of homogenization efficiency in milk.

- 1.7. Constructional details, operation and maintenance of HTST pasteurizer.

- 1.8. Constructional details, operation and maintenance of pouch filling machine.

- 1.9. Constructional details, operation and maintenance of multiple-effect evaporator.

- 1.10. Constructional details, operation and maintenance of spray drier.

- 1.11. Constructional details, operation and maintenance of reverse osmosis and ultra-filtration system.

Suggested Readings

- Ahmed, T. 1985. Dairy Plant System Engineering. Kitab Mahal, K.L. Agencies Pvt. ltd., New Delhi.

- Ahmed, T. 1990. Dairy Plant System Engineering and Management. Kitab Mahal, K.L. Agencies Pvt. ltd., New Delhi.

- Anantakrishnan, C.P. and Simha, N. N. 1987. Technology and Engineering of Dairy Plant Operations. Laxmi Publ., Delhi.

- Food Engineering Operations. 1969. Elsevier Publ. Co., Amsterdam, New York.

- Farrall, A. W. 1963. Engineering for Dairy and Food Products. John Wiley and Sons, New York.

- Gardner, A. W. 1971. Industrial drying. Leonard Hill Publ., London.

- Food Engineering and Dairy Technology. V. A. Kessler Publ., Freising, Germany.1981.

2. Dairy Starters in Fermented Milk Products (1+2+0) (CUDP2241)

Theory

- 2.1. Concept, importance and types of starter cultures in dairy industry.

- 2.2. Modern trends in propagation, production and preservation methods of starter cultures (liquid, spray drying, vacuum drying, freeze-drying, frozen concentrate, concentrated dried cultures, DVS Starters).

- 2.3. Metabolism of starter cultures (carbohydrate, protein, citrate).

- 2.4. Production of metabolites and antibacterial compounds by starters.

- 2.5. Starter defects and failures.

- 2.6. Bacteriophages of dairy starters and their impact on dairy industry.

- 2.7. Lactic acid bacteria as probiotics in development of health foods.

- 2.8. Role of starters in the preparation of various fermented milks (dahi, yoghurt, acidophilus milk and Yakult) and its associated defects.

- 2.9. Nutritional and therapeutic significance of fermented milks.

- 2.10. Cheese Starters: Bacterial and mold ripened cheeses, Rennet substitutes.

Practice

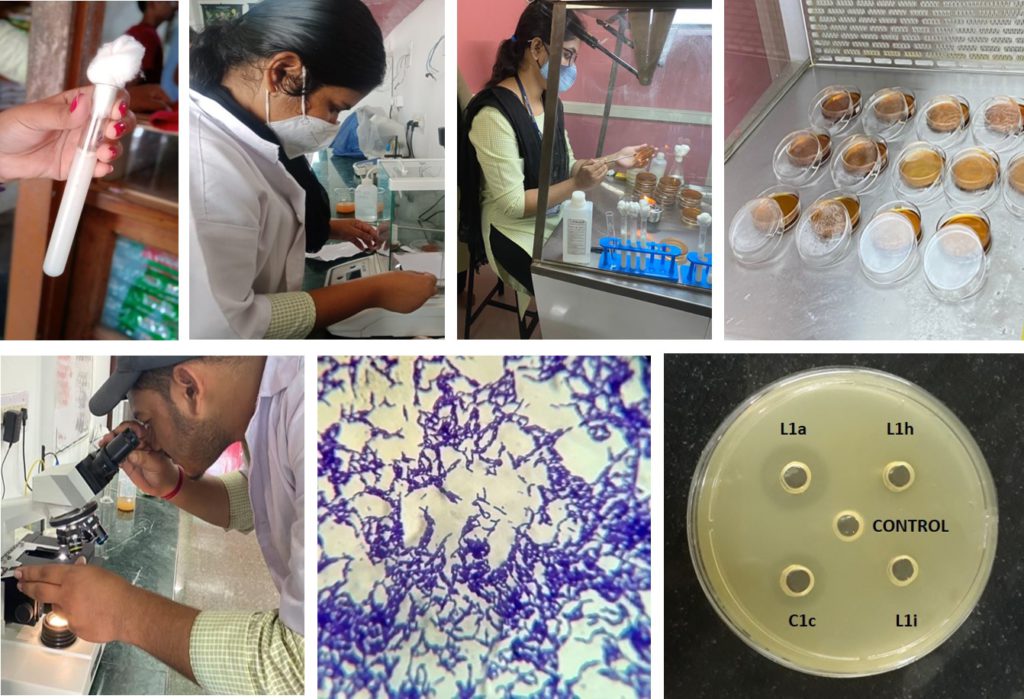

- 2.1. Testing purity of starter cultures by Gram’s staining, catalase test; creatine test

- 2.2. Testing starter activity by dye reduction tests, Horrell-Elliker, White Head & Cox test.

- 2.3. Preparation of sterilized reconstituted skim milk and propagation of starter cultures.

- 2.4. Preservation of starter cultures by freeze-drying techniques.

- 2.5. Preparation of DVS starters.

- 2.6. Effect of physical factors (temperature, pH, salt and Sugar) on dairy starters.

- 2.7. Effect of the presence of antibiotic residues in milk on starter activity.

- 2.8. Detection of bacteriophages in cheese whey by plaque assay method.

- 2.9. Microbial quality of milk for preparation of fermented milk.

- 2.10. Preparation and microbial examination of dahi, yoghurt and cultured buttermilk.

- 2.11. Analysis of cheese for total spore count.

Suggested Readings

- Marth & Steele- Applied Dairy Microbiology- 2nd ed. Taylor and Francis, New York

- Cogan, T. M. and Accolas, J. P. (1995). Dairy Starter Cultures. VCH Publ., USA.

- Farnworth, E. R. (2008). Handbook of Fermented Functional Foods. 2nd ed. CRC Press, USA.

- Tamime, A Y. and Robinson, R. K. (1999). Yoghurt Science and Technology, 2nd ed. Woodhead Publ. Ltd. and CRC Press LLC, USA.

3. Quality Assurance in Dairy Industry (1+2+0) (CUDP2242)

Theory

- 3.1. Awareness about Quality and Safety of Dairy Foods: Concepts of quality control, quality assurance and food safety; Global quality and food safety standards, Integrated food law, its main features and functions.

- 3.2. Introduction to Food Safety Management System: Concepts of Quality Management System (QMS)–ISO: 9000:2000, ISO: 22000; Principles of QMS; Standard requirements for QMS

- 3.3. HACCP concept and principle with special reference to biological hazards in dairy foods, TQM tools and techniques.

- 3.4. Role of national and international food regulatory systems and standards: with respect to quality and safety of milk and milk products: FSSAI, PFA, AGMARK, BIS ISO, IDF, Codex, etc.

- 3.5. Introduction of risk assessment; Biosafety concepts in handling of dairy pathogens and setting up of a microbiological/ pathogen lab in a dairy plant.

- 3.6. Setting up of testing facilities and analytical laboratories; the concept of mobile testing laboratories. Accreditation of analytical laboratories.

- 3.7. Preparation and standardization of reagents required in the analysis of milk and milk products.

- 3.8. Sampling plan and testing methods for the detection of adulterants, preservatives and neutralizers in milk and milk products.

- 3.9. Environmental contaminants such as pesticides, antibiotics, heavy metals in milk and milk products; Importance of milk contact surfaces, metallic contamination in the dairy industry.

- 3.10. Concepts of hygiene and sanitation in dairy plant, treatment and disposal of wastewater and effluents.

Practice

- 3.1. Standardization of glassware for quality analysis.

- 3.2. Preparation and testing of Gerber sulfuric acid used in fat determination. Testing the amyl alcohol used for fat determination.

- 3.3. Preparation and standardization of dairy reagents such as acids, alkali solutions etc.

- 3.4. Chemical analysis of permissible additives used in milk and milk products.

- 3.5. Chemical analysis of detergents and sanitisers.

- 3.6. Detection of adulterants, preservatives, and neutralizers in milk and milk products. Analysis of market samples of milk and milk products.

- 3.7. Determination of temporary and permanent hardness of water.

- 3.8. Estimation of available chlorine from bleaching powder.

- 3.9. Rapid detection of antibiotic residues in milk using Delvo SP

- 3.10. Microbiological tests for assessing Environmental, equipment and personnel hygiene by swab and rinse methods.

- 3.11. Quality evaluation by HACCP in the preparation of dairy products.

Suggested Readings

- Alli, I. (2004). Food Quality Assurance: Principles and Practices. CRC Press, Boca Raton, USA.

- Herschdoerfer, S. M. (2004). Quality Control in the Food Industry. Vol. I & II. Academic Press, London.

- Jacobs, M. B. (1999). Chemical Analysis of Food and Food Products. CBS Distributors, New Delhi.

- Kramer, A. and Twigg, B. A. (Eds). (1966). Fundamentals of Quality Control for the food industry, The AVI Publ. Co., West Port, Conn., USA.

- PDF ...

4. Dairy Products Development (0+3+0) (CUDP2243)

Practice

- 4.1. Classification of traditional Indian dairy products.

- 4.2. Preparation of pasteurized milk.

- 4.2. Preparation of standardized milk.

- 4.3. Preparation of flavoured milk.

- 4.4. Preparation of a khoa (a heat desiccated milk product).

- 4.5. Preparation of a peda (a heat desiccated milk product).

- 4.5. Preparation of a burfi (a heat desiccated milk product).

- 4.6. Preparation of a kalakand (a heat desiccated milk product).

- 4.7. Preparation of a milk cake (a heat desiccated milk product).

- 4.8. Preparation of a khoa based sweet Gulabjamun (a heat desiccated milk product).

- 4.9. Preparation of a Rasogulla (an acid heat coagulated milk product).

- 4.10. Preparation of a Rabri and Basundi (a heat desiccated milk product).

- 4.11. Preparation of cereal-based milk products (rice kheer/payasam).

- 4.12. Preparation of a channa and studying the factors affecting its quality and yield.

- 4.13. Preparation of paneer and studying the factors affecting its quality and yield (an acid heat coagulated milk product)

- 4.14. Preparation of herbal lassi (a value-added dairy drink).

5. Synbiotic Dairy Foods (0+3+0) (CUDP2244)

Practice

- 5.1. Basic concepts of probiotics, prebiotics and synbiotics.

- 5.2. Sampling and isolation of probiotic microorganisms.

- 5.3. Staining and microscopic characterization of probiotic candidates.

- 5.4. Maintenance and preservation of isolated probiotic cultures.

- 5.5. Traditional process of identification based on biochemical methods.

- 5.6. Determination of acid tolerance activity.

- 5.7. Determination of transit tolerance to bile salts.

- 5.8. Cell surface hydrophobicity (CSH) Assays

- 5.9. Bile salt hydrolase (BSH) activity.

- 5.10. Antimicrobial activity of probiotic candidates.

- 5.11. Antibiotic susceptibility test of probiotic cultures.

- 5.12. Determination of antioxidative activity by ABTS Method.

- 5.13. Determination of antioxidative activity against FRAP Method.

- 5.14. Determination of antioxidative activity by DPPH method.

- 5.15. Cell auto-aggregation ability by the selected probiotic candidate.

- 5.16. Determination of cell adherence ability by probiotic cells

- 5.17. Types and classification of prebiotics

- 5.18. Preparation of synbiotic curd/yoghurt

- 5.19. Production of synbiotic whey drink

6. Quality Analysis of Milk and Milk Products (0+3+0) (CUDP2245)

Practice

- 6.1. Platform tests of milk in the receiving dock.

- 6.2. Determination of acidity of milk

- 6.3. Determination of density, specific gravity and pH of milk

- 6.4. Determination of fat content of milk

- 6.5. Determination of total solids and protein content of milk

- 6.6. Determination of lactose content of milk

- 6.7. Determination of ash content of milk

- 6.8. Quality evaluation of paneer (moisture, fat, protein)

- 6.9. Quality evaluation of khoa (moisture, fat, protein)

- 6.10. Quality evaluation of butter (fat, moisture, salt)

- 6.11. Quality evaluation of ghee (acidity, moisture)

- 6.12. Determination of RM and PV of ghee

- 6.13. Determination of peroxide value of ghee

- 6.14. Quality evaluation of Dahi and fermented beverages.

- 6.15. Detection of common adulterants in milk from the market.

- 6.16. Detection of added neutralizers in milk.

- 6.17. Detection of the presence of vegetable oil in ghee.

- 6.18. Estimation of microbial load in raw milk by standard plate count (SPC), coliform, yeast and mould.

- 6.19. Determination of microbial load by dye reduction test (MBRT).

- 6.20. Characterization of gram-positive and gram-negative bacteria using Gram's staining method.

7. Project & Industrial Internship (0+0+10) (CUDP2246)

Project

- 7.1. Dairy product development and value addition.

- 7.2. Functional Dairy food and health applications.

- 7.3. Food preservation, biopreservation of dairy foods

- 7.4. Quality and safety assessment of dairy food and food products.

- 7.5. Probiotics, prebiotics and synbiotics dairy foods

Session Plan for the Entire Domain:

1. Milk Processing in Dairy Industry (1+2+0) (CUDP2240)

Theory

Session 1.1: Collection and Transportation of milk: Organization of milk collection routes, practices for collection of milk, preservation at farm, refrigeration, natural microbial inhibitor, reception, chilling, classification and storage.

Session 1.2: Standardization of milk: Addition or removal of milk fat to make different milk products, numericals.

- Standardization-of-Milk

- Standardization of milk ...

Session 1.3: Mechanical Separation: Sedimentation, Filtration, Centrifugal separation, Bactofugation.

Session 1.4: Homogenization: Classification, power requirement, care and maintenance.

Session 1.5: Pasteurization: Batch, flash and HTST pasteurization

Session 1.6: Packaging machines: Pouch filling machine pre-pack and aseptic filling bulk handling system

Session 1.7: Mixing and agitation: Theory and purpose of mixing, Equipment used

Session 1.8: Evaporation: Basic principles and classification

Session 1.9: Drying: Drum drying, Spray drying

Session 1.10: Membrane processing: Ultra filtration, Reverse Osmosis and electro dialysis, Materials for membrane construction, Ultra filtration of milk, Effect of milk constituents on operation, membranes for electro-dialysis.

Practice

Session 1.1: Familiarization with equipments for reception of milk in plant, platform test.

Session 1.2: Cream separation: parts of separator and the process.

Session 1.3: Preparation of special milks: toned and double toned milk.

Session 1.4: Detection of adulterant and preservatives in milk.

Session 1.5: Constructional details, operation and maintenance of homogenizers.

Session 1.6: Assessment of homogenization efficiency in milk.

Session 1.7: Constructional details, operation and maintenance of HTST pasteurizer.

Session 1.8: Constructional details, operation and maintenance of pouch filling machine.

Session 1.9: Constructional details, operation and maintenance of multiple effect evaporator.

Session 1.10: Constructional details, operation and maintenance of spray drier.

Session 1.11: Constructional details, operation and maintenance of reverse osmosis and ultra-filtration system.

2. Dairy Starters in Fermented milk Products (1+2+0) (CUDP2241)

Theory

Session 2.1: Concept, importance and types of starter cultures in dairy industry.

Session 2.2: Modern trends in propagation, production and preservation methods of starter cultures (liquid, spray drying, vacuum drying, freeze-drying, frozen concentrate, concentrated dried cultures, DVS Starters).

Session 2.3: Metabolism of starter cultures (carbohydrate, protein, citrate).

Session 2.5: Starter defects and failures.

Session 2.6: Bacteriophages of dairy starters and their impact on dairy industry.

Session 2.7: Lactic acid bacteria as probiotics in development of health foods.

- Lactic acid bacteria as probiotics in development of health foods ....

- Video Link 1 ...

- Video Link 2 ...

Session 2.8: Role of starters in the preparation of various fermented milks (dahi, yoghurt, acidophilus milk and Yakult) and its associated defects.

Session 2.9: Nutritional and therapeutic significance of fermented milks.

- Nutritional and therapeutic properties of fermented milks ...

- Online Source: ...

Session 2.10: Cheese Starters: Bacterial and mold ripened cheeses, Rennet substitutes.

Practice

Session 2.1: Testing purity of starter cultures by Gram’s staining, catalase test; creatine test.

Session 2.2: Testing starter activity by dye reduction tests, Horrell-Elliker, White Head & Cox test.

Session 2.3: Preparation of sterilized reconstituted skim milk and propagation of starter cultures.

Session 2.4: Preservation of starter cultures by freeze-drying techniques.

Session 2.5:

- Preparation of DVS starters.

Session 2.6: Effect of physical factors (temperature, pH, salt and Sugar) on dairy starters.

Session 2.7: Effect of presence of antibiotic residues in milk on starter activity.

Session 2.8:

- Detection of bacteriophages in cheese whey by plaque assay method.

- Video Link 2 ...

Session 2.9:

- Microbial quality of milk for preparation of fermented milks.

- Video Link ...

Session 2.10: Preparation and microbial examination of dahi, yoghurt and cultured butter milk.

Session 2.11: Analysis of cheese for total spore count.

3. Quality Assurance in Dairy Industry (1+2+0) (CUDP2242)

Theory

Session 3.1: Awareness about Quality and Safety of Dairy Foods: Concepts of quality control, quality assurance and food safety; Global quality and food safety standards, Integrated food law, its main features and functions.

Session 3.2: Introduction to Food Safety Management System: Concepts of Quality Management System (QMS)–ISO: 9000:2000, ISO: 22000; Principles of QMS; Standard requirements for QMS

Session 3.3: HACCP concept and principle with special reference to biological hazards in dairy foods, TQM tools and techniques.

- Video Link ...

- 8&t=60s

- Concept of HACCP

Session 3.4: Role of national and international food regulatory systems and standards: with respect to quality and safety of milk and milk products: FSSAI, PFA, AGMARK, BIS ISO, IDF, Codex, etc.

- Role of national food regulatory systems and standards ...

- Role of inter-national food regulatory systems and standards ...

- Slide share: Web Link

- Slide share: Web Link

Session 3.5: Introduction of risk assessment; Biosafety concepts in handling of dairy pathogens and setting up of a microbiological/ pathogen lab in a dairy plant.

Session 3.6: Setting up of testing facilities and analytical laboratories; concept of mobile testing laboratories. Accreditation of analytical laboratories.

Session 3.7: Preparation and standardization of reagents required in the analysis of milk and milk products.

- Preparation and standardization of reagents required in the analysis of milk ...

- Video Link 1 ...

- Video Link 2 ...

Session 3.8: Sampling plan and testing methods for the detection of adulterants, preservatives and neutralizers in milk and milk products.

Session 3.9: Environmental contaminates such as pesticides, antibiotics, heavy metals in milk and milk products; Importance of milk contact surfaces, metallic contamination in dairy industry.

- Milk contaminants (pesticide and antibiotics) ...

- Heavy metals ...

- Method of analysis of milk contaminanta, updated ...

- Video Link ...

Session 3.10: Concepts of hygiene and sanitation in dairy plant, treatment and disposal of waste water and effluents.

Practice

Session 3.1: Standardization of glasswares for quality analysis.

Session 3.2: Preparation and testing of Gerber sulfuric acid used in fat determination. Testing the amyl alcohol used for fat determination.

Session 3.3: Preparation and standardization of dairy reagents such as acids, alkalis solutions etc.

Session 3.4: Chemical analysis of permissible additives used in milk and milk products.

Session 3.5:Chemical analysis of detergents and sanitizers.

Session 3.6: Detection of adulterants, preservatives, and neutralizers in milk and milk products. Analysis of market samples of milk and milk products.

Session 3.7: Determination of temporary and permanent hardness of water.

Session 3.8: Estimation of available chlorine from bleaching powder.

Session 3.9: Rapid detection of antibiotic residues in milk using Delvo SP

Session 3.10: Microbiological tests for assessing Environmental, equipment and personnel hygiene by swab and rinse methods.

Session 3.11: Quality evaluation by HACCP in the preparation of dairy products.

4. Dairy Products Development (0+3+0) (CUDP2243)

Practice

Session 4.1: Classification of traditional Indian dairy products. (1h)

Session 4.2: Preparation of pasteurized milk. (1h)

Session 4.3: Preparation of a flavoured milk. (1h)

Session 4.4: Preparation of a khoa (a heat desiccated milk product). (2h)

Session 4.5: Preparation of a peda (a heat desiccated milk product). (2h)

Session 4.6: Preparation of a kalakand (a heat desiccated milk product). (1h)

Session 4.7: Preparation of a milk cake (a heat desiccated milk product). (2h)

Session 4.8: Preparation of a khoa based sweet gulabjamun (a heat desiccated milk product). (2h)

Session 4.9: Preparation of a rasogulla (a acid heat coagulated milk product). (2h)

Session 4.10: Preparation of a rabri and basundi (a heat desiccated milk product). (2h)

Session 4.11: Preparation of a cereals based milk products (rice kheer/payasam). (2h)

Session 4.12: Preparation of a channa and studying the factors affecting its quality and yield. (2h)

Session 4.13: Preparation of a paneer and studying the factors affecting its quality and yield (a acid heat coagulated milk product). (2h)

Session 4.14: Preparation of a herbal lassi (a value added dairy drinks). (2h)

Session 4.15: Preparation of butter and factors affecting its quality and yield. (2h)

5. Synbiotic Dairy Foods (0+3+0) (CUDP2244)

Session 5.1: Basic concepts of probiotics, prebiotics and synbiotics.

Session 5.2: Sampling and isolation of probiotic microorganisms.

Session 5.3: Staining and microscopic characterization of probiotic candidates.

Session 5.4: Maintenance and preservation of isolated probiotic cultures.

Session 5.5: Traditional process of identification based on biochemical methods.

Session 5.6: Determination of acid tolerance activity.

Session 5.7: Determination of transit tolerance to bile salts.

Session 5.8: Cell surface hydrophobicity (CSH) Assays

Session 5.9: Bile salt hydrolase (BSH) Activity

Session 5.10: Antimicrobial activity of probiotic candidates

Session 5.11: Antibiotic susceptibility test of probiotic cultures

Session 5.12: Determination of antioxidative activity by ABTS Method

Session 5.13: Determination of antioxidative activity against FRAP Method

Session 5.14: Determination of antioxidative activity against DPPH Method

Session 5.15: Cell auto-aggregation ability by selected probiotic candidate

Session 5.16: Determination of cell adherence ability by probiotic cells

Session 5.17: Types and classification of prebiotics

Session 5.18: Preparation of synbiotic curd/yoghurt

Session 5.19: Production of synbiotic whey drink

6. Quality Analysis of Milk and Milk Products (0+3+0) (CUDP2245)

Practice

Session 6.1: Platform tests of milk in the receiving dock.

Session 6.2: Determination of acidity of milk

Session 6.3: Determination of density, specific gravity and pH of milk

Session 6.4: Determination of fat of milk

Session 6.5: Determination of total solids and protein content of milk

Session 6.6: Determination of lactose content of milk

Session 6.7: Determination of ash content of milk

Session 6.8: Quality evaluation of paneer (moisture, fat, protein)

Session 6.9: Quality evaluation of k hoa (moisture, fat, protein)

Session 6.10: Quality evaluation of butter (fat, moisture, salt)

Session 6.12: Determination of RM and PV of ghee

Session 6.13: Determination of peroxide value of ghee

Session 6.14: Quality evaluation of dahi and fermented beverage

Session 6.15: Detection of common adulterants in milk from the market.

Session 6.16: Detection of added neutralizers in milk.

Session 6.17: Detection of the presence of vegetable oil in ghee.

Session 6.18: Estimation of microbial load in raw milk by standard plate count (SPC)coliform, yeast and mold.

Session 6.19: Determination of microbial load by dye reduction test (MBRT).

Session 6.20: Characterization of gram-positive and gram-negative bacteria using gram staining method

7. Projects in Units/Industry/Lab (0+0+10) (CUDP2246)

Project

To acquire more experience, students will work in the following places:

- Dairy Processing Units/ Laboratories

- Dairy Industry/Cooperatives

- Research Institutes

Student’s Project:

- Antimicrobial activity of Lactobacillus species against common dairy pathogens isolated from indigenous dairy products

- A comparative study between microwave and HTST pasteurizer processing on milkshelf-life

- Preparation and characterization of low fat and low sugar herbal lassi

Latest News & Student Testimonials

Media

Our Main Teachers

Dr. Rajashree Jena is currently working as Assistant Professor in the Department of Dairy Technology, Centurion University of Technology and Management, Paralakhemundi Campus, Odisha. She has obtained her Ph. D degree from National Dairy Research Institute, Karnal in the field of Dairy Microbiology. She has more than 3 years of research and teaching experience at […]

Dr. Prasanta Kumar Choudhury is currently working as Assistant Professor and Head in the Department of Dairy Technology, Centurion University of Technology and Management, Paralakhemundi Campus, Odisha. He obtained his Ph. D degree from the National Dairy Research Institute, Karnal in the field of Dairy Microbiology. He has more than 7 years of experience at […]

3. Dr. Soma Maji is working as an Assistant Professor in the Department of Dairy Technology, Centurion University of Technology and Management, Paralakhemundi, Odisha. She is B.Tech in Dairy Technology, M.Tech in Dairy Chemistry from WBUAFS, Nadia, West Bengal and Ph.D. in Dairy Chemistry from NDRI, Karnal. She has published more than 7 research, popular […]