Computational Fluid Dynamics (CFD) is the process of mathematically modeling a physical phenomenon involving fluid flow and solving it numerically using computational prowess. In the present scenario, the Computationaltechniques easily complement the experimental and theoretical techniques in solving the problems with high complexity as the computation reduces the engineering testing costs, product-to-market time, and costs as well as provides comprehensive data which are not easily obtainable from experimental tests. Hence CFD is routinely used today in a wide variety of disciplines and industries, including aerospace, automotive, power generation, chemical manufacturing, polymer processing, petroleum exploration, medical research, meteorology, astrophysics, etc.

Domain Track: Computational Fluid Dynamics

Course Attendees

Still no participant

Course Reviews

Still no reviews

Track Total Credits ( 2+10+8)

Course Division( list all divisions):

- CUCF2180 Introduction to CFD (2+0+1)

- CUCF2181 Grid Generation (0+2+0)

- CUCF2182 Flow Solver Techniques-Simulia (0+3+1)

- CUCF2183 Simulation and Validation (0+5+0)

- CUCF2184 Industry Specific Project (0+0+6)

Domain Track Objectives:

The motive behind the CFD Domain is to predict a complex turbulent flow field obtained through interactions amongst multiple sources of fluid flow in a three-dimensional mostly confined by multiple solid boundaries and even in presence of a strong pressure gradient and under other influences of a variety of body forces as well. Such general-purpose codes find wide application in the design and performance evaluation of a variety of industrial application problems. Right now the CFD Domain facilitates the SIMULIA platform offered by Dassault Systems to handle complex CFD problems from industries. This domain enables

- To provide the knowledge of CFD in the Industrial Level.

- To apply CFD methods as a tool for design, analysis and engineering applications.

Domain Track Learning Outcomes:

- To impart knowledge about various computational methods for fluid flow and heat transfer problems so as to enable the students to write computer programs for solving elementary fluid dynamics/heat transfer problems.

- To execute the industry projects so as to produce Quality products to the Clients.

Career Scopes in CFD:

- Code development

- Development of various modules of CFD software

- Can be for general purpose software or for codes for specific application

- Application of CFD software

- For solving industrial problems in diverse areas

- Testing & Validation of CFD codes

- Usually for QA of multipurpose commercial software

- Documentation for CFD codes

- Writing technical documents like user guides for commercial CFD codes

Domain Syllabus:

1. Introduction to CFD (2-0-1)

Module-1

- Fluid, Properties of Fluid (Temperature, Vapour Pressure, Viscosity, Specific Gravity, Compressibility, Speed of Sound, Density, Energy, Specific Heat, Newtonian and Non-Newtonian Fluids

Module-2

- Lagrangian and Eulerian Approaches, Classification of Fluid Flow (Inviscid vs. Viscous, Laminar vs. Turbulent, Incompressible vs. Compressible, Internal vs. External, Steady vs. Unsteady,Rotational vs. Irrotational, 1D, 2D and 3D Flows)

- Project 1. Case studies in industrial pipe flows.

Module-3

- Governing Equations of Flow Field (Conservation of Mass, Momentum (Navier-Stoke Equation) and Energy)- Differential Form, Integral Form.

- Project 2. Case studies and generation of drag and lift for flow over bodies.

Module-4

- Flow Features (Stagnation, Boundary Layer (Laminar to Transition to Turbulent), Flow Separation), Types of Boundary Conditions.

- Project 3. Case studies in different types of aerofoil and its applications.

Module-5

- Heat Transfer in Fluid (Conduction, Convection (Natural, Forced), Radiation), Non-dimensional Quantities, Flow Similarity between Prototype and Model.

- Project 4. Case studies for various non-dimensional quantities and its importance in CFD.

Module-6

- CFD and its applications, Discretization methods for the CFD (FDM, FVM, FEM, Hybrid Methods).

- Project 5. Case studies for the various applications of CFD and its significance.

Module-7

- Turbulence Modelling, CFD Solution Tool Chain

- Project 6. Case studies for the different turbulence modelling in CFD.

Text Book:

- An Introduction to Computational Fluid Dynamics, by H.K.Versteeg & W.Malalasekera, Longman Scientific & Technical, England

2. Grid Generation (0-2-0)

- 2.1 Introduction to Meshes- CFD Meshing Basics

- 2.2 Different Element Shapes- Creating, Managing & Updating Meshes

- 2.3 CFD Meshing- 2D Mesh, 3D Mesh, Mapped Face Meshing,

- Practice 1. 2D mapped Mesh for rectangular pipe

- Practice2. 2D mapped Meshing for Aerofoil.

- 2.4 Structured Meshing, Un-Structured Mesh, Sweep 3D Mesh

- Practice 3. 3D structure mesh of Circular Cylinder

- Practice 4. 3D unstructured mesh with prims layers for Aerofoil

- Practice 5. 3D coarse/ medium/ fine sweep mesh for pipe

- Practice 6.3D coarse/ medium/ fine unstructured Octree Tetrahedron mesh for Aerofoil.

- Practice 7. 3D hex- dominant mesh for rectangular Duct.

- 2.5 Visualization the Mesh- Visualization Management, Mesh Visualization Options, Section, Clipping Box, Mesh colour, Element shrink

- 2.6 Reviewing the Mesh- Quality Analysis, free Edges, Interfaces, Duplicate Checker, Isolate Node Checker

- Practice 8. 3D hex-dominant with surface mesh, Boundary prim mesh for DS car.

- Practice 9. 3D Tetrahedron filler mesh Narrowing pipe.

- Practice 10. 3D Tetrahedron, surface, for Electronics Module.

- Practice 11. 3D Sweep mesh for circular cylinder.

- Practice 12. 3D mesh generation for Subsonic Converging-diverging Nozzel.

- Practice 13. 3D Sweep mesh generation for U-Bend pipe.

- Practice 14. 3D mesh generation of Dimple Ball.

- Practice 15. 3D mesh generation of a wedge body.

Text Book:

- HandBook of Grid Generation, by J.F.Thompson, B.K.Soni & N.P.Weatherill, CRC Press , New York.

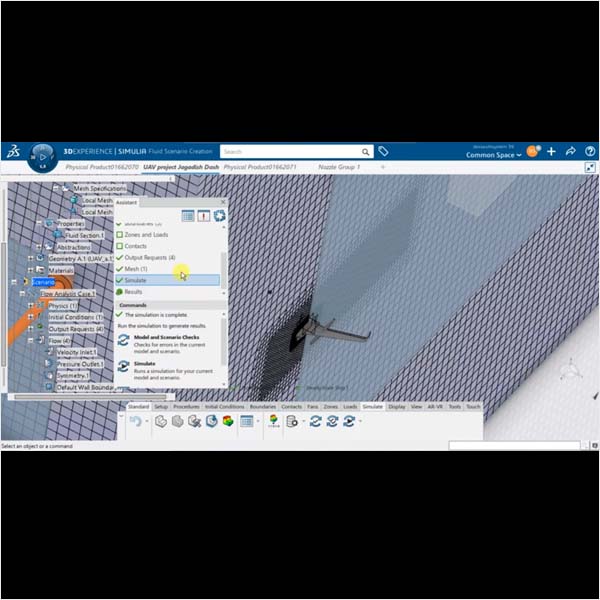

3. Flow Solver Techniques-SIMULIA (0-3-1)

- 3.1 Overview-Fluid Dynamics Engineer Essentials

- Connecting to the platform, Assigning roles and Apps, Platform Interface, Importing 3D XML file, Simulation Conventions in the 3DExperience Platform

- Practice 1. Getting Started with the 3DExperience Platform.

- 3.2 Import an assembly

- Explore the imported assembly, Renamed the assembly, Search for parts/assemblies in the database, open parts/ assemblies found through search, duplicate, delete and save entities, Import a 3D XML file containing fluid materials, Create and save a new material.

- 3.3 Fluid Dynamics Engineer Role Overview

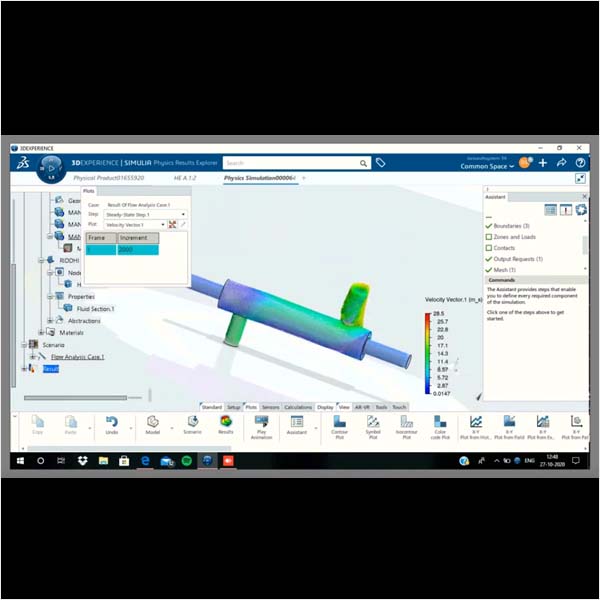

- Exploring Fluid Dynamics Engineer Role Apps, CFD simulations work flow, Model preparations, Material definitions, Meshing, CFD analysis, Analysis convergence, co-simulation Analysis, Post processing results, CFD solver validations.

- Practice 2. CFD analysis of steady state internal Laminar Pipe flow.

- Project 1. Analysis of pipe flow at Re= 500.

- 3.4 Getting Started with CFD Simulations

- Fluid Model Creation, Fluid Scenario Creation App Interface, Model setup, applying meshing, Scenario Setup, Results visualizations, Reviewing Simulation Features,

- Practice 3. CFD analysis Steady-state external flow over an Airfoil.

- Project 2. Analysis of 2D cylinder in a rectangular domain with varying radius and height.

- 3.5 Geometry for CFD Simulations

- Geometry Preparation- Check and Repair, Defeature Idealize, Create, Healing, Join, Local Join, surface connection Checker, Face checker, Mid surface

- Practice 4. Modeling of Air intake system.

- Practice 5. Extracting Fluid volume for Engine Manifold.

- 3.6 Material and Section Properties of Fluid

- Understanding materials, working with materials, Creating a new Material, Applying a Material, Adding New Domains, Editing a Material Domain, Simulation Domain, Material Behaviors in a Simulation Domain, Section Properties, working with Imported Meshes

- 3.7 Defining Physics of Fluid

- Analysis Procedures- Enabling Temperature, Compressible, Coupled vs Segregated solver, Gravity effects.

- Turbulence Modelling- SST k-w, Realizable k-e, Spalart-Almaras, Radiation Modeling, Steady-state Analysis, Transient Analysis- Courant-Freidrichs-Levy (CFL) condition, Grid Independence Study, Bad cell Treatment

- Practice 6. Grid Independence study for above cases (pipe / airfoil) using different solver schemes.

- Project 3. Analysis of flow an over a circular cylinder at Re=107.

- Practice 7. Conjugate Heat Transfer (CHT) Analysis of an Electronics Module.

- Project 4. Analysis of temperature rise through cross flow heat exchanger.

- 3.8 Boundary and Initial Conditions

- Boundary Conditions, wall boundary conditions, Thermal wall boundary, Initial Conditions, Initializing Compressible flows, Turbulence Specifications at Boundaries, Surface- to – surface Radiation specification at Boundaries, Time- dependent Boundary Conditions, Spatially- Varying Boundary conditions, User defined Boundary conditions.

- 3.9 Turbulence Modeling & Modeling Techniques.

- Practice 8. Aerodynamics analysis of DS car.

- Practice 9. Unsteady Flow across a Circular Cylinder.

- Practice 10. Transonic Flow over an Airfoil.

- Project 5. Analysis and estimation of Drag lift coefficients flat plate at Re=10,000.

- 3.10 Solution Convergence

- Practice 11. Cavitating Flow through a Narrowing Pipe.

- Project 6. Analysis of compressible flow nozzle with atmospheric pressure at the nozzle exit.

- 3.11 Post-processing Results.

- Practice 12. Creating Post processing reports for all the above cases.

4. Simulation and Validation (0-5-0)

- 4.1 Fluid flow in the rear duct of an automotive HVAC system.

- 4.2 CFD Analysis of an Air intake system.

- 4.3 CFD Steady-state External flow over a Drone in cruise.

- 4.4 DE featuring of a Lens Component.

- 4.5 CFD analysis for Conjugate Heat Transfer in a fan –cooled CPU Board.

- 4.6 CFD analysis Energy computations in a Contact Analysis.

- 4.7 Thermo-mechanical Analysis of a Laser Powder Bed Fusion Build.

- 4.8 CFD analysis in Turbulent pipe flow.

- 4.9 CFD Supersonic flow analysis for 3D cone.

- 4.10 CFD analysis over a Ahmed body.

5. Industry Specific Projects (0-0-6)

- ( Selected Projects will be carried out)

- 5.1 CFD Analysis of economizer in a tangential fired boiler.

- 5.2 Analysis and comparison of vertical tube with smooth tube.

- 5.3 A CFD-based analysis of the 14-bis aircraft aerodynamics and stability.

- 5.4 CFD analysis of gas flow behaviour in economizer duct.

- 5.5 Combined aerodynamic and structural optimization of a high-speed civil transport wing.

- 5.6 Fluid flow and temperature distribution in radiators used in automobiles.

- 5.7 Analysis of Cyclone dust collector air flow.

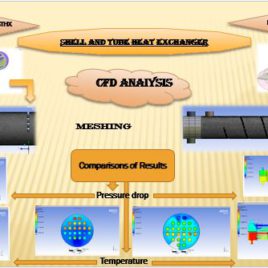

- 5.8 CFD analysis of shell and tube heat exchanger with fins for waste heat recovery application.

- 5.9 A theoretical analysis and CFD simulation on the on the ceramic monolith heat exchanger.

- 5.10 Analysis of water flow for Laminar & Turbulent Flow in Conventional Water Tap.

- 5.11 CFD Investigation of Airflow on a SANTRO Zing Car by using Fluent.

- 5.12 CFD analysis of rocket nozzle.

- 5.13 CFD analysis of supersonic exhaust in a scramjet engine.

- 5.14 Aerodynamic Design for Bus/Car Vehicle.

- 5.15 CFD analysis of exhaust manifold.

- 5.16 CFD analysis of centrifugal fan.

- 5.17 Analysis of intake manifold in SI engines.

- 5.18 CFD modelling of the automobile catalytic converter.

- 5.19 CFD analysis of fluid flow and heat transfer in a single tube-fin arrangement of an automotive radiator.

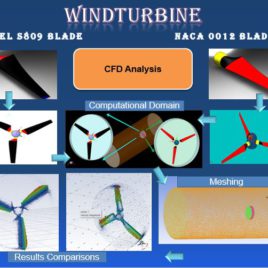

- 5.20 Computational flow field analysis of a vertical axis wind turbine.

Session Plan for the Entire Domain:

1. Introduction to CFD (2-0-1)

Session 1

- Fluid, Streamline, Path line & Streak line.

- Video Link 1...

- Video Link 2...

Session 2

- Properties of Fluid -Temperature, Vapour Pressure, Viscosity, Specific Gravity, Compressibility.

- Video Link 1...

- Video Link 2...

- Video Link 3...

- Video Link 4...

- Video Link 5...

Session 3

- Properties of Fluid -Speed of Sound, Density, Energy, Specific Heat.

- Video Link 1...

- Video Link 2...

- Video Link 3...

- Video Link 4...

Session 4

- Newtonian and Non-Newtonian Fluids.

- Video Link...

Session 5

- Lagrangian and Eulerian Approaches.

- Video Link...

Session 6

- Classification of Fluid Flow - Inviscid vs. Viscous, Laminar vs. Turbulent, Internal vs. External.

- Video Link 1...

- Video Link 2...

- Video Link 3...

Session 7

- Steady vs. Unsteady, Incompressible vs. Compressible Flows, Rotational vs. Irrotational Flows.

- Video Link 1...

- Video Link 2...

- Video Link 3...

Session 8

- Descriptions of 1D, 2D and 3D Flows.

- Video Link...

Session 9 & 10

Project 1(Assignment).

- Case studies in industrial pipe flows.

Session 11

- Governing Equations of Flow Field- Differential and Integral Forms of Conservation of Mass

- Video Link...

Session 12

- Differential and Integral Forms of Conservation of Momentum (Navier-Stokes Equation)

- Video Link...

Session 13

- Differential and Integral Forms of Conservation of Energy

- Video Link...

Session 14 & 15

Project 2(Assignment).

- Case studies and generation of drag and lift for flow over bodies.

Session 16

- Flow Features- Stagnation Point Flow, Boundary Layer Flow, Boundary Layer Thickness

- Video Link 1...

- Video Link 2...

Session 17

- Flow Separation- Laminar to Transition to Turbulent

- Video Link...

Session 18

- Types of Boundary Conditions

Session 19 & 20

Project 3(Assignment).

- Case studies in different types of aerofoil and its applications

Session 21

- Heat Transfer in Fluid- Conduction, Convection (Natural, Forced), Radiation.

- Video Link...

Session 22

- Non-dimensional Quantities.

Session 23

- Flow Similarity between Prototype and Model

- Video Link...

Session 24 & 25

Project 4(Assignment).

- Case studies for various non-dimensional quantities and its importance in CFD.

Session 26

- CFD and its applications.

- Video Link...

Session 27

- Discretization methods for the CFD -Finite Difference Method.

- Video Link...

Session 28

- Finite Volume Method.

- Video Link...

Session 29

- Finite Element Method and Hybrid Method

- Video Link...

Session 30 & 31

Project 5(Assignment).

Case studies for the various applications of CFD and its significance.

Session 32

- Turbulence Modelling- Calculation of Y+ value, Wall Functions.

- Video Link...

Session 33

- k-e & k-w models.

- Video Link...

Session 34

- CFD Solution Tool Chain

- Video Link...

Session 35 & 36

Project 6(Assignment).

- Case studies for the different turbulence modelling in CFD.

2. Grid Generation (0-2-0)

Sessions 37 & 38

Practice 1.

- 2D mapped Mesh for rectangular pipe

- Video Link...

Sessions 39 & 40

Practice 2.

- 2D mapped Meshing for Aerofoil.

- Video Link...

Sessions 41 & 42

Practice 3.

- 3D structure mesh of Circular Cylinder

- Video Link...

Sessions 43 & 44

Practice 4.

- 3D unstructured mesh with prims layers for Aerofoil.

- Video Link...

Sessions 45 & 46

Practice 5.

-

- 3D coarse/ medium/ fine sweep mesh for pipe.

Sessions 47 & 48

Practice 6.

- 3D coarse/ medium/ fine unstructured Octree Tetrahedron mesh for Aerofoil.

- Video Link...

Sessions 49 & 50

Practice 7

- 3D hex- dominant mesh for rectangular Duct.

- Video Link...

Sessions 51 & 52

Practice 8.

- 3D hex-dominant with surface mesh, Boundary prim mesh for DS car.

- Video Link...

Sessions 53 & 54

Practice 9.

- 3D Tetrahedron filler mesh Narrowing pipe.

- Video Link...

Sessions 55 & 56

Practice 10.

- 3D Tetrahedron, surface, for Electronics Module.

- Video Link...

Sessions 57 & 58

Practice 11.

- 3D Sweep mesh for circular cylinder.

- Video Link...

Sessions 59 & 60

Practice 12.

- 3D mesh generation for Subsonic Converging-diverging Nozzel.

- Video Link...

Sessions 61 & 62

Practice 13.

- 3D Sweep mesh generation for U-Bend pipe.

- Video Link...

Sessions 63 & 64

Practice 14.

- 3D mesh generation of Dimple Ball.

- Video Link...

Sessions 65 & 66

Practice 15.

- 3D mesh generation of a wedge body.

- Video Link...

3. Flow Solver Techniques- SIMULIA (0-3-1)

Sessions 67 & 68

Practice 1.

- Getting Started with the 3DExperience Platform.

Sessions 69 & 70

Practice 2.

- CFD analysis of steady state internal Laminar Pipe flow.

Sessions 71 & 72

Project 1.

- Analysis of pipe flow at Re= 500.

Sessions 73 & 74

Practice 3.

- CFD analysis Steady-state external flow over an Airfoil

Sessions 75 & 76

Project 2.

- Analysis of 2D cylinder in a rectangular domain with varying radius and height.

Sessions 77 & 78

Practice 4.

- Modeling of Air intake system.

Sessions 79 & 80

Practice 5.

- Extracting Fluid volume for Engine Manifold.

Sessions 81 & 82

Practice 6.

- Grid Independence study for above cases (pipe / airfoil) using different solver schemes.

Sessions 83 & 84

Project 3.

- Analysis of flow an over a circular cylinder at Re=107.

Sessions 85 – 88

Practice 7.

- Conjugate Heat Transfer (CHT) Analysis of an Electronics Module.

Sessions 89 & 90

Project 4.

- Analysis of temperature rise through cross flow heat exchanger.

Sessions 91- 94

Practice 8.

- Aerodynamics analysis of DS car.

Sessions 95 & 96

Practice 9.

- Unsteady Flow across a Circular Cylinder.

Sessions 97- 100

Practice 10.

- Transonic Flow over an Airfoil.

Sessions 101 & 102

Project 5.

- Analysis and estimation of Drag lift coefficients flat plate at Re=10,000.

Sessions 103 - 106

Practice 11.

- Cavitating Flow through a Narrowing Pipe.

Sessions 107 & 108

Project 6.

- Analysis of compressible flow nozzle with atmospheric pressure at the nozzle exit.

Sessions 109 & 110

Practice 12.

- Creating Post processing reports for all the above cases.

4. Simulation and Validation (0-5-0)

Each Practice: 6 Hrs.

- Grid Generation-1Hr. + Simulation-3 Hrs.+ Validation-2 Hrs.)

Sessions 111 – 116

Practice 1.

- Fluid flow in the rear duct of an automotive HVAC system.

Sessions 117 – 122

Practice 2.

- CFD Analysis of an Air intake system.

Sessions 123 – 128

Practice 3.

- CFD Steady-state External flow over a Drone in cruise.

Sessions 129 – 134

Practice 4.

- DE featuring of a Lens Component.

Sessions 135 - 140

Practice 5.

- CFD analysis for Conjugate Heat Transfer in a fan –cooled CPU Board.

Sessions 141 - 146

Practice 6.

- CFD analysis Energy computations in a Contact Analysis.

Sessions 147 - 152

Practice 7.

- Thermo-mechanical Analysis of a Laser Powder Bed Fusion Build.

Sessions 153 – 158

Practice 8.

- CFD analysis in Turbulent pipe flow.

Sessions 159 – 164

Practice 9.

- CFD Supersonic flow analysis for 3D cone.

Sessions 165 - 170

Practice 10.

- CFD analysis over a Ahmed body.

5. Industry Specific Projects (0-0-6)

Each Project: Minimum 10 Hrs.

- Developing a Tentative Schedule with Milestones: 1Hr.

- Planning and Assigning Different Job Roles-1Hr.

- Designing/ Developing/Importing the Product- 1Hr.

- Simulating the Product- 3Hrs.

- Evaluating the solution and Validation- 4Hrs.

Sessions 171 – 180

Project 1.

- CFD Analysis of economizer in a tangential fired boiler.

- Video Link...

Sessions 181 – 190

Project 2.

- CFD analysis of gas flow behaviour in economizer duct

- Video Link...

Sessions 191 – 200

Project 3.

- Fluid flow and temperature distribution in radiators used in automobiles

- Video Link...

Sessions 201 – 210

Project 4.

- Analysis of Cyclone dust collector air flow

- Video Link...

Sessions 211 – 220

Project 5.

- CFD analysis of shell and tube heat exchanger with fins for waste heat recovery application

- Video Link...

Sessions 221 – 230

Project 6.

- CFD Investigation of Airflow on a SANTRO Zing Car

- Video Link...

Sessions 231 – 240

Project 7.

- CFD analysis of supersonic exhaust in a scramjet engine.

- Video Link...

Sessions 241 – 250

Project 8.

- A CDF-based analysis of the 14-bis aircraft aerodynamics and stability

- Video Link...

Sessions 251 – 260

Project 9.

- Computational flow field analysis of a vertical axis wind turbine

- Video Link...

List of Projects/ papers/jobs/products to be done in domain:

List of Projects:

- CFD Analysis of economizer in a tangential fired boiler.

- Analysis and comparison of vertical tube with smooth tube.

- A CFD-based analysis of the 14-bis aircraft aerodynamics and stability.

- CFD analysis of gas flow behaviour in economizer duct.

- Combined aerodynamic and structural optimization of a high-speed civil transport wing.

- Fluid flow and temperature distribution in radiators used in automobiles.

- Analysis of Cyclone dust collector air flow.

- CFD analysis of shell and tube heat exchanger with fins for waste heat recovery application.

- A theoretical analysis and CFD simulation on the on the ceramic monolith heat exchanger.

- Analysis of water flow for Laminar & Turbulent Flow in Conventional Water Tap.

- CFD Investigation of Airflow on a SANTRO Zing Car by using Fluent.

- CFD analysis of rocket nozzle.

- CFD analysis of supersonic exhaust in a scramjet engine.

- Aerodynamic Design for Bus/Car Vehicle.

- CFD analysis of exhaust manifold.

- CFD analysis of centrifugal fan.

- Analysis of intake manifold in SI engines.

- CFD modelling of the automobile catalytic converter.

- CFD analysis of fluid flow and heat transfer in a single tube-fin arrangement of an automotive radiator.

- Computational flow field analysis of a vertical axis wind turbine.

Latest News & Student Testimonials

Media

Our Main Teachers

Prof. Ashok Misra is a Professor in the Department of Mathematics, School of Applied Sciences, Paralakhemundi Campus and the Head of the Center for Computational Mathematics, Centurion University of Technology and Management, Odisha. He has obtained his Ph.D. in Mathematics on the topic entitled “Study on Different Aspects of Two-Phase Flow Phenomena” from Berhampur University, […]

Dr. Mukundjee Pandey completed his B.Tech in Mechanical Engineering from Sikkim Manipal Institute of Technology Majitar East-Sikkim. He obtained his M. Tech. in Thermal Science and Heat Power engineering specialization from Institute of Technical Education and Research, Siksha ‘O’ Anusandhan University, Bhubaneswar in 2015. He has completed his PhD from International Institute of Information Technology, […]

Dr. Sujit Mishra is presently an Assistant professor and Head of the Mechanical Engineering Department at Centurion University of Technology and Management, Paralakhemundi campus. He has ten years of teaching experience with subject interests such as Machine Design,Fluid mechanics, Computational Fluid Dynamics, Computer-Aided Drafting, Computer-Aided Engineering, and Computer-Aided Manufacturing at both UG and PG levels. […]