Industrial automation is essential in present day’s modern industries. Industrialautomation is often understood as automating a process, but in real sense it’s much more than that. Today we require product accuracy, price competitiveness, flexible product line, safety, and more products in less time, all of these are addressed by industrial automation. Industrial automation is a multidisciplinary approach, as for designing and maintaining an automatic system, requires knowledge from all disciplines of engineering.

Domain Track: Industrial Automation

Course Attendees

Still no participant

Course Reviews

Still no reviews

Track Total Credits ( T-P-P) (5-9-10)

Courses Division( list all divisions):

- Brief introduction to Industrial Automation 1-0-0

- Advanced programming & control blocks of PLC 1-2-0

- Control & signal wiring of PLC 0-2-0

- SCADA based advanced features 1-1-0

- SCADA & PLC based sequential control 0-1-0

- Human Machine Interface 1-2-0

- OPC server base data fetching & control 1-1-0

- Project 0-0-6

- Internship 0-0-4

Domain Track Objectives:

Industrial automation domain is both interactive as well as hands-on. After gaining knowledge about this domain, students can get easily absorbed in industries as most of the product and process industries prefer students who have knowledge about industrial automation. As the application and implementation of Industrial automation is very vast so students have a choice to choose their career in whichever part they are strong in. We aim to upgrade knowledge levels needed for modern industries, Process & sequential control logic of industry. This will cover topics such as Programmable Logic Controllers (PLCs), Human Machine Interface (HMI), Supervisory Control and Data Acquisition (SCADA) with latest Industrial Automation software and hardware.

- To upgrade knowledge levels needed for modern industries

- Process & sequential control logic of industry.

- Project based training

Career Scope:

- Industrial Automation Engineer.

- Instrumentation & Control (I&C) Engineer

- SCADA Developer.

- PLC Project/service engineer.

- Process/Field/DCS operator.

- DCS Engineer.

- Higher studies and ResearchSelf-employment through entrepreneurship

Domain Track Learning Outcomes:

- Gain knowledge on advanced industrial automation

- Understand different types of Devices to which PLC input and output modules are connected

- Provide the knowledge about understand various types of mobile applications.

- Industry based project & advanced learning.

Domain Syllabus:

Course - 1

Brief introduction to industrial automation :

- 1.1 Automation Uses

- 1.2 Automation - PLC Basics

- 1.3 Mechanical relays versus PLC

- 1.4 Functions of various blocks and working principle of advanced blocks.

Course - 2

ADVANCED PROGRAMMING & CONTROL BLOCKS OF PLC

- 2.1 CPT, ADD, SUB, MUL, DIV, SQR, NEG, TOD, FRD

- 2.2 MOV,MVM, AND, OR, XOR, NOT. CLR.

- 2.3 BSL, BSR, SQC, SQL,SQO, FFL,FFU,LFL,LFU

- 2.4 JMP,LBL,JSR,MCR

- 2.5 Connecting PLC software with SCADA software

Practice

- P2.1 - Comparison of industry based analog signals.

- P2,2 - Detecting different product output of an industry

- P2.3 - Sequential control of an industry by using advanced blocks.

- P2.4 - Emergency control system of a industry

- P2.5 Connecting PLC software with SCADA software

Course - 3

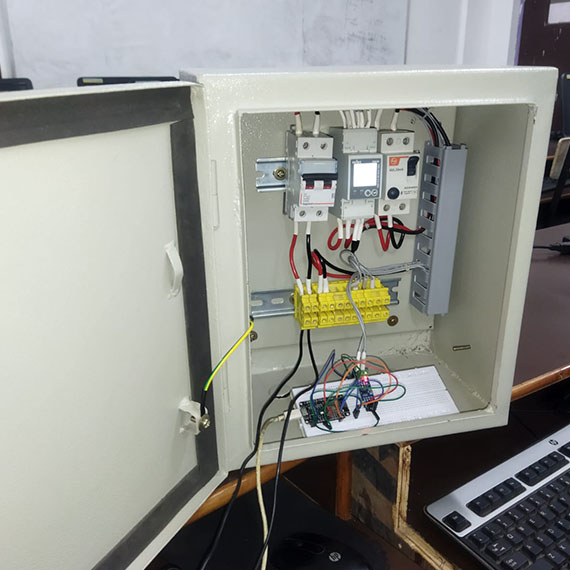

CONTROL & SIGNAL WIRING OF PLC

- 3.1 Control wiring of PLC.

- 3.2 PLC, Sensor and field instruments signal flow wiring.

- 3.3 Device connectivity

Practice

- P3.1 PLC input/output wiring concept.

- P3.2 Connecting relay, contactor, sensors and other field instruments.

- P3.3 Controlling an industry motor using STAR-DELTA connection

Course - 4

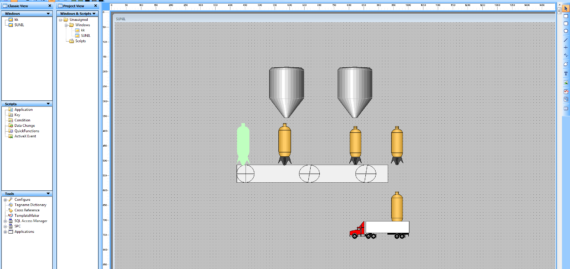

SCADA BASED ADVANCED FEATURES

- 4.1 Alarms

- 4.2 Trends, Data base connectivity & Report generation

- 4.3 Recipe management

- 4,4 Security.

Practice :

- P4.1 - Data fetching and representing on graph and excel

- P4.2 - Advanced controlling of industry by using SCADA

Course - 5

SCADA & PLC BASED SEQUENTIAL CONTROL

- 5.1 Script

- 5.2 Networking

- 5.3 Device connectivity.

Practice :

- P5.1 Script

- P5.2 Networking

- P5.3 Device connectivity

Course - 6

HUMAN MACHINE INTERFACE

- 6.1 What is HMI. Use of HMI

- 6.2 Concept of different operational features

- 6.3 Connectivity of HMI and PLC.

Practice :

- P6.1 Alarms

- P6.2 Security

- P6.3 Recipe manager

Course - 7

OPC SERVER BASE DATA FETCHING & CONTROL

- 7.1 Study of Open Platform Communications

- 7.2 OPC to control PLC, SCADA .

- 7.3 OPC based different protocol concept.

- 7.4 Data handling using OPC.

Practice :

- P7.1 Installation of OPC

- P7.2 OPC protocols

- P7.3 Connectivity of PLC, SCADA & ARDUINO to OPC.

PROJECT

- 1.Automation of Callander machine in waste to wealth lab.

- 2.Automation of substation at the university.

- 3.Sanitary incinerator.

- 4. Automatic gate control of entrance of buses.

INTERNSHIP

- Prasad Seeds (Hyderabad)

Session Plan for the Entire Domain:

Module - 1

Brief introduction to industrial automation:

- Session 1: Automation Uses

- Session 2: Automation - PLC Basics

- Session 3: Mechanical relays versus PLC

- Session 4: Functions of various blocks and working principle of advanced blocks.

- PPT: Introduction & brief ideas...

- Video Link 1...

- Video Link 2...

- Video Link 3...

Module - 2

ADVANCED PROGRAMMING & CONTROL BLOCKS OF PLC

- Session 5: CPT, ADD, SUB, MUL, DIV, SQR, NEG, TOD, FRD

- Session 6: MOV,MVM, AND, OR, XOR, NOT. CLR.

- Session 7: BSL, BSR, SQC, SQL,SQO, FFL,FFU,LFL,LFU

- Session 8: JMP,LBL,JSR,MCR

Practice :

- P2.1 - Comparison of industry based analog signals.

- P2.2 - Detecting different product output of an industry

- P2.3 - Sequential control of an industry by using advanced blocks.

- P2.4 - Emergency control system of a industry

- P2.5 Connecting PLC software with SCADA software

- Ladder logic Video Link...

- Practice : Video Link...

- PDF : IA Lecture - 10 Math...

- IA Lecture - 11 Mov-Log...

- IA Lecture - 13 Shift-Seq...

- IA Lecture - 14 Shift-Seq 2...

- Video Link...

Module - 3

CONTROL & SIGNAL WIRING OF PLC

- Session 9: Control wiring of PLC.

- Session 10: PLC, Sensor and field instruments signal flow wiring. Device connectivity

Practice :

- P3.1- PLC input/output wiring concept.

- P3.2 -Connecting relay, contactor, sensors and other field instruments.

- P3.3- Controlling an industry motor using STAR-DELTA connection

- Practice : Video Link...

- PPT : sensors...

- PDF : IA Lecture - 15 Program...

- Video Link...

Module - 4

SCADA BASED ADVANCED FEATURES

- Session 11: Alarms

- Session 12: Trends, Data base connectivity & Report generation

- Session 13: Recipe management

- Session 14: Security.

Practice :

- P4.1 - Data fetching and representing on graph and excel

- P4.2 - Advanced controlling of industry by using SCADA

- PPT : SCADA...

- SCADA : Video Link...

Module - 5

SCADA & PLC BASED SEQUENTIAL CONTROL

- Session 15: Script

- Session 16: Networking

- Session 17: Device connectivity.

Practice :

- P5.1 - Script

- P5.2 - Networking

- P5.3 - Device connectivity

- PPT : SCADA & PLC...

- SCADA PLC : Video Link...

Module - 6

HUMAN MACHINE INTERFACE

- Session 18: What is HMI. Use of HMI

- Session 19: Concept of different operational features

- Session 20: Connectivity of HMI and PLC.

Practice :

- P6.1 - Alarms

- P6.2 - Security

- P6.3 - Recipe manager

- PDF : HMI...

- HMTHMI Video Link...

Module - 7

OPC SERVER BASE DATA FETCHING & CONTROL

- Session 21: Study of Open Platform Communications Kepserver.

- Session 22: OPC to control PLC, SCADA.

- Session 23: OPC based different protocol concept.

- Session 24: Data handling using OPC.

Practice :

- P7.1 - Installation of OPC

- P7.2 - OPC protocols

- P7.3 - Connectivity of PLC, SCADA to OPC.

- PPT : OPC...

- OPC: Video Link...

- Video Link...

- Video Link...

List of Projects/ papers/jobs/products to be done in domain:

Gate Process to Project

- Gate 0: Project Identification

- Gate 1: Planning

- Gate 2: Modelling

- Gate 3: Design and simulation

- Gate 4: Documentation

PROJECT :

- Automation of Callander machine in waste to wealth lab.

- Automation of substation at the university.

- Sanitary incinerator.

- Automatic gate control of entrance of buses.

PAPERS :

- SMART HELMET- '' THE KEY FOR SECURED LIFE

- Driver less vehicle.

JOBS :

- Prasad Seeds (Hyderabad)

INTERNSHIP :

- Prasad Seeds (Hyderabad)

Software and Hardware

1. PLC and HMI Hardware

2. SCADA Software

Latest News & Student Testimonials

Media

Our Main Teachers

Dr.Amit Kumar Sahoo receivedhis PhD from Birla Institute of Technology, Mesra, India in Control System and Master’s degree from National Institute of Technology, Rourkela, India. He is presently working as an Assistant Professorin the Department of Electrical & Electronics Engineering, Centurion University of Technology and Management, Odisha, India. He has total 12 years of teaching […]

Mr. Joy Choudhury is presently working as Project Manager in the Department of Electrical & Electronics Engineering, Centurion University of Technology and Management, Odisha. He has total 9 years of experience in the field of Industrial Automation and control. His specializations include programming, commissioning and training on Distributed Control System (DCS), (Programmable Logic Controller) PLC, […]