This skill course specializes in utilization, installation and maintenance of Solar Thermal Technologies for supply of process heat in industry. This course encompasses National Occupational Standards (NOS) and aligned with NSQF level 5 of “Solar Thermal Engineer - Industrial Process Heat," Qualification Pack (SGJ/Q0603) issued by “Skill Council for Green Jobs (SCGJ) of India”.

Solar Thermal Engineer-Industrial Process Heat

Course Attendees

Still no participant

Course Reviews

Still no reviews

Code(Credit) : CUTM3078(0-2-2)

| Scheme | Skill for Success (SFS) |

| NSQF Level | 5 |

| Duration | 4 Months |

| Sector | Skill Council for Green Jobs (SCGJ) |

| Occupations | Design, installation and maintenance |

| Entry Qualification | ITI/Diploma/B. Tech/Applied Science/ Agriculture |

| Minimum Age | 16 Years |

| Aligned to (QP) | SGJ_Q0603_Solar-Thermal-Engineer-Industrial-Process-Heat_v0.pdf |

| Document | https://course.cutm.ac.in/courses/solar-thermal-engineer-industrial-process-heat/ |

Course Objectives:

The objectives of this subject are:

- To make the students understand the principles of types of Solar Collectors and apply them for solving practical problems.

- To introduce the principles and design of Types of solar energy Storage Systems and its Application

- To understand the test and commissioning process of Solar Thermal system

- To carry out the specification, fabrication process, safety tools during project site.

After completing this program-

- The trainee will be exposed to design solar thermal technologies solutions for industrial process heat applications.

- The trainee will be ensured installation, testing and commissioning of solar thermal systems

- The trainee will be able to carry out proper maintenance of solar thermal systems

- The trainee will maintain personal health & safety at the solar thermal project site

- Can join the industry as solar thermal installer of various solar thermal systems and can become solar thermal Project manager.

- Can become an entrepreneur in the related field.

- Can do a Diploma or any Advance program or will do research work in the same

Learning Record:

The trainee will submit a Practice/Project/Learning record after each class/session.

Assessment Process:

- The assessment agencies should have an expert to conduct assessment NOS wise and every trainee should score a minimum of 70% in the overall assessment.

- The assessment of the theory/knowledge will be based on a written test/viva-voce or both while the skill test shall be hands-on practical.

Course Syllabus/Contents:

- Practice: Maintenance of proper cleaning of reflectors/ collectors Practice: Checking of reflectors/collectors for any defects Practice: Checking of the receivers for damage Practice: Checking the receivers for black coating/ selective coating and in case of fading of paint

List of Projects/Products/Publications :

1.Project: Development of Hybrid type of solar dryer by using liquid flat plate collector

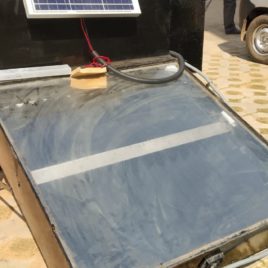

2.Project: Development of Box type of solar cooker by using reflector

3.Project: Development of Parabolic Trough concentrator by using magnifying glass for water heating purpose.

4.Project: Development of solar dish type of solar cooker

5.Project: Development of Evacuated Tube type of solar collector

6.Project: Development of Forced convection type of solar dryer by using liquid flat plate collector

Reference Book :

1. DP Kothari, KC Singal, and R Ranjan, Renewable Energy Sources and Emerging Technologies, Prentice hall, New Delhi, 2008.

2. VVN Kishore, Renewable Energy Engineering and Technology: principles and practice, Teri, India, 2008

3. SS Das, DD Behera, and NC Giri, Clean Energy Applications in Modern World, Notion Press, ISBN: 9781638069560, 2021.

4. SS Das, DD Behera, and A.Pradhan, Clean Energy Products: A Path for Attaining Livelihood Security, Notion Press, ISBN: 9781636691602, 2020.

Session Plan:

- Foundation (online)- (1)Sharing the success stories of the area/course so far (2) Sharing clear road map to deliver the course (3) List of Projects/Products they have to make.

- Demo – Demonstration about Solar Thermal collector.

- Practice - Design and Modeling of liquid flat plate collector

- Foundation (online) - Description of portable type parabolic trough collector.

- Demo – Demonstration of demo model of portable type parabolic trough collector and identification Fresnel reflector.

- Practice - Design and Modeling of portable type parabolic trough collector.

- Foundation (online) - Description of different components and specification of different type of solar cooker.

- Demo- Demonstration of demo model of parabolic dish type and box type cooker.

- Practice- Design and Modeling of parabolic dish type and box type cooker.

- Foundation (online) - Description of different components of Evacuated type of solar collector.

- Demo - Demonstration of Solar water heater by Evacuated tube collector (ETC).

- Practice - Design and Modelling of Evacuated Tube type solar collector.

- Foundation (online) - Site survey for computing the shadow free open area available on the ground or rooftop for installation of solar thermal system.

- Demo - Demonstration of Forced convection type of solar dryer.

- Practice - Design and Modeling of Forced convection type solar dryer

- Study materials:

- Forced convection solar dryer-pdf

- Foundation (online) - Analyze solar radiation data for the project site.

- Demo - Demonstration of different components of Hybrid type solar dryer.

- Practice - Design and Modelling of Hybrid type solar dryer

- Foundation (online) – Concept of concentrating and receiver mounting structure.

- Demo - Installation of concentrating collectors and receiver mounting structures.

- Practice - Thermal analysis of fluid flowing through the absorbing tube of Parabolic Trough concentrator.

- Web link :

- Foundation (online) - Analyze designs and drawings of solar thermal system.

- Demo - Demonstration of concentration ratio and material selection of reflectors.

- Practice - Installation and orientation of reflectors/ collector

- Foundation (online) - Material selection of Evacuated type of solar collector.

- Demo - Demonstration of Receiver tube of Evacuated type of solar collector.

- Practice - Installation of Evacuated type of solar collector.

- Web link :

- Foundation (online) – Concept of pyranometer, pyrhelometer, Sunshine recorder.

- Demo - Demonstration of different types of solar measuring instrument.

- Practice - Measurement of solar radiation and temperature by using LUX Meter and pyrometer.

- Web link :

- Foundation (online) –Material selection of solar dryer.

- Demo - Demonstration of different components of solar dryer..

- Practice - Performance Testing of Forced convection type of solar dryer

- Demo – Demonstration of efficiency of Hybrid type solar dryer.

- Practice - Performance Testing of Hybrid type solar dryer

- Web link :

- Demo - Demonstration of material selection and efficiency calculation of solar cooker.

- Practice - Performance testing of Box type of solar cooker

- Demo – Demonstration on efficiency calculation and material selection of dish type of solar cooker.

- Practice - Performance testing of dish type of solar cooker

- Demo - Demonstration on efficiency calculation and focus point calculation of Parabolic Trough concentrator.

- Practice - Performance testing of Parabolic Trough concentrator

- Web link :

- Demo- Carry out testing of the piping network for any leakages and rectify accordingly if any defects found.

- Practice -Commission of the solar thermal system.

- Web link :

- Foundation (online) - Maintenance of proper cleaning of reflectors/ collectors.

- Demo - Check the receiver pipes, receivers and heat delivery pipes for scale formation periodically and carry out de-scaling of pipes with descaling chemicals using descalar system.

- Practice - Commissioning of proper working of tracking system

- Foundation (online) - Identification of corporate policies required for work safety.

- Demo - Identification of the location of first aid materials.

- Practice- Checking of the receivers for damage and checking the receivers for black coating/ selective coating and in case of fading of paint.

- Web link :

- Foundation (online) - Identification of the personal protection equipment required for specific locations on-site.

- Demo - Demonstration of fault finding and testing of a Solar system.

- Practice - Identification of environmental hazards, personal safety and work site associated with the project site.

- Web link :

- Foundation (online) -Consult and assist others to maximize effectiveness and efficiency in carrying out tasks, display appropriate communication etiquette while working.

- Demo - Demonstrate responsible and disciplined behaviours at the workplace; ensure collaboration and group participation to achieve common goals.

- Practice - Facilitate an understanding and appreciation of the differences among team members

Industry Partnership :

Latest News & Student Testimonials

CUTM3078 | SKILL: Experimental set up of Solar dish type of cooker | CUTM

CUTM3078 | SKILL: Experimental set up of Solar parabolic Trough collector | CUTM

CUTM3078 | Experiment conducted on Solar hybrid type of dryer | CUTM

CUTM3078 |Experimental set up of Solar box type cooker 1 | CUTM

Media

Our Main Teachers

Assistant professor, Mechanical Engineering Department Centurion University of Technology and Management Bhubaneswar, Odisha- 752050, India